TM 5-4310-369-14

Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

General

Preventive Maintenance Checks and Services

To ensure that the air compressor is ready for operation

a. This paragraph contains a tabulated listing of pre-

ventive maintenance services which must be performed by

at all times, it must be inspected systematically so that de-

fects may be discovered and corrected before they will re-

organizational maintenance personnel at quarterly intervals.

sult in serious damage or failure. Defects discovered during

A quarterly interval is equal to 3 calendar months, or 250

operation of the units shall be noted for future correction,

hours of operation, whichever occurs first.

to be made as soon as operation has ceased. Stop operation

b. The item numbers are listed consecutively and in-

dicate the frequency of minimum requirements. Refer to

immediately if a deficiency is noticed which would damage

the equipment if operation were continued. All deficiencies

It should be noted that the item number column is used as

and shortcomings will be recorded together with the cor-

a source of item numbers for the TM number column on

rective action taken on DA Form 2404 (Equipment In-

DA Form 2404 Equipment Inspection and Maintenance

spection and Maintenance Worksheet) at the earliest

Worksheet, in recording results of Preventive Maintenance

possible opportunity.

Checks and Services.

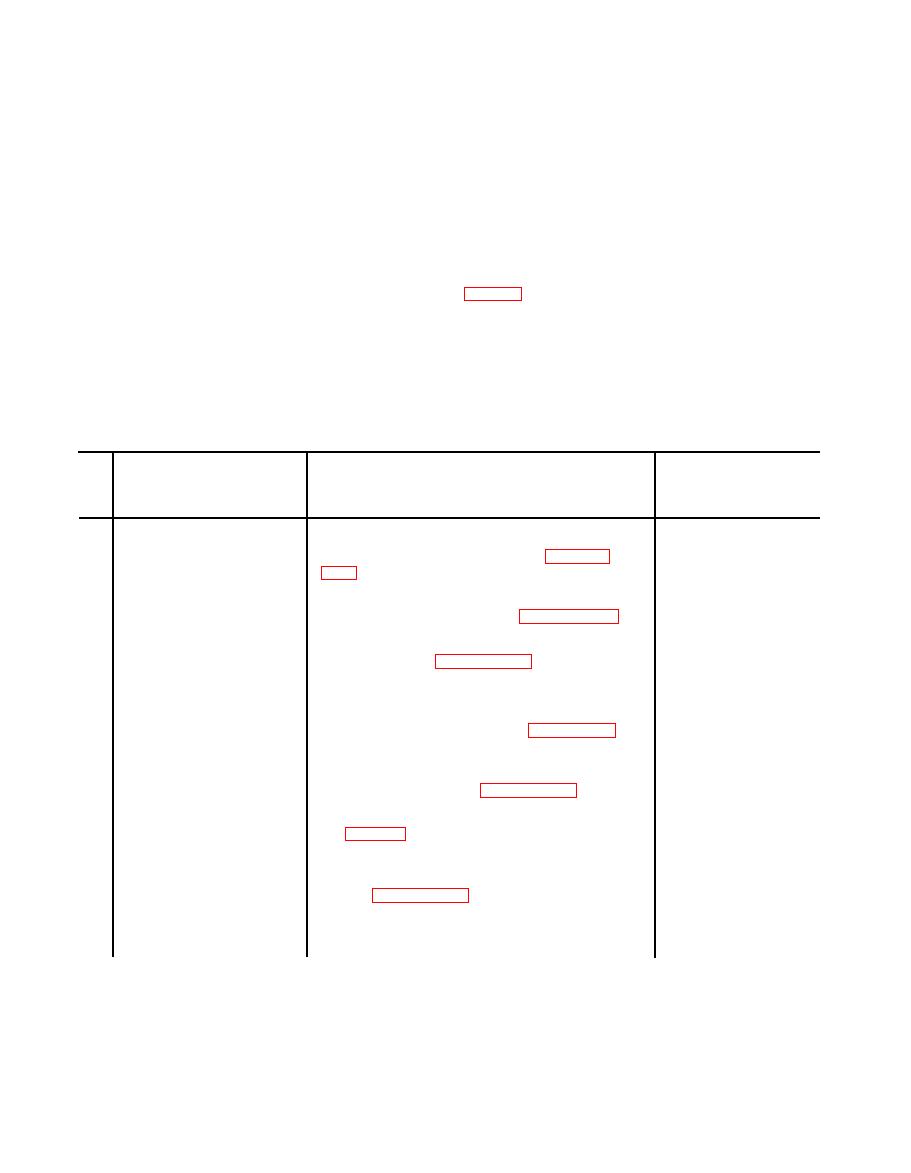

For Readiness Reporting,

Procedures Check For And Have

Item

Repaired, Replaced, Adjusted

Equipment Is Not

Item To Be Inspected

No.

As Necessary

Ready/Available If

Drive Belts

Inspect for improper tension, excessive wear and

1

Belts are cracked.

cracked or frayed condition. Refer to paragraph

Inspect for leaks, damage, and loose connections.

2

Aftercooler and Intercooler

Replace a defective tube. Refer to paragraph 4-20.

Inspect for improper operation and insecure

Relief Valve

3

Valve leaks.

mounting. Refer to paragraph 4-18.

4

Inspect for damage and insecure mounting. With

Constrols and Instruments

Controls are damaged

the unit operating, check for improper operation.

or missing.

5

Inspect for leaks and damage. Refer to paragraph

Air Receiver Tank

Tank leaks.

4-21.

6

Check fuel level. Inspect for leaks, loose and

Fuel Tank

Tank leaks.

missing hardware. Refer to paragraph 4-11.

7

Check oil level. Add oil as indicated on sight glass.

Compressor Crankcase Oil

Oil level is low.

Level

See table 3-1 for proper type of oil to use.

8

Tires, Tubes and Wheels

Inspect for cuts, foreign objects and damage. Check

air pressure. Proper pressure is 25 psi (1 .75 kg/sq cm).

Refer to paragraph 4-24.

Engine Oil Level

9

Check oil level. Add oil as indicated on oil gage.

Oil level is low.

See figure 3-2 for proper type of oil to use.