TM 5-4310-369-14

Table 4-2. Troubleshooting-Continued

Malfunction

Test or Inspection

Corrective Action

Step 4. Check to determine if engine is at correct speed.

Operation of this equipment presents a noise hazard to personnel in the area. The noise level exceeds the

allowable limits for unprotected personnel. Wear ear muffs or earplugs which were fitted by a trained

professional.

Adjust the engine speed governor control to obtain correct speed. Refer to engine maintenance manual

TM 5-2805-256-14 for procedure.

2.

EXCESSIVE OIL CONSUMPTION.

Step 1. Check for "wrong type" or "inferior grade" of oil.

Step 2. Check compressor for oil leaks and oil weeping at bolts, nuts and gasket areas. Secure bolts and nuts to

correct torque. Gaskets that leak should be replaced if leaking continues after fastenings are tightened.

Step 3. Check crankcase breather for correct operation. Figure 3-5. Vent hole must be free and clear.

3.

NOISY OPERATION.

Step 1. Check for loose external parts.

Examine compressor carefully, tightening any loose bolts, screws, nuts, or other threaded parts that might

be generating noise.

Step 2. Check for pulley striking intercooler coil.

a. Bend the coils toward base so they clear pulley.

b. If pulley still strikes coil, proceed as follows.

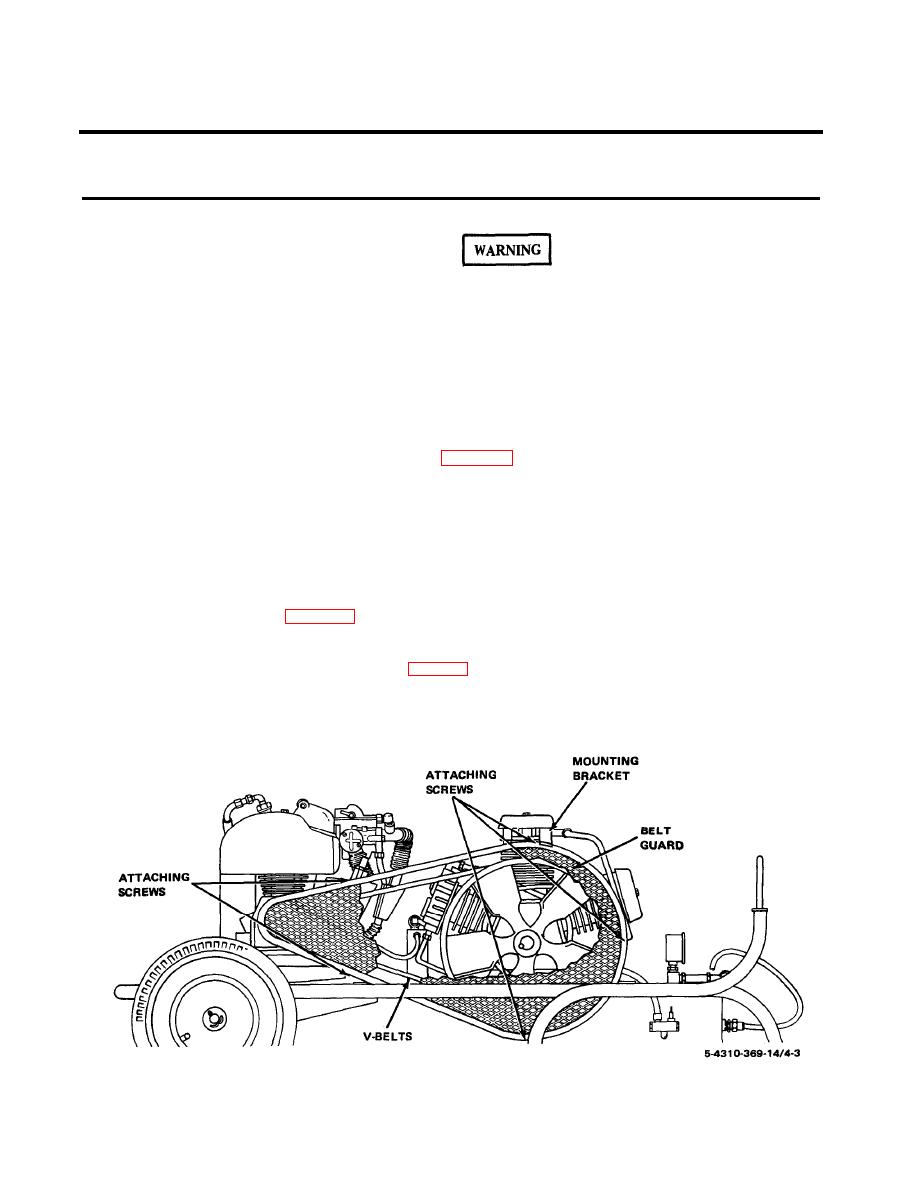

(1) Refer to figure 4-3 for removal of belt guard.

(2) Loosen setscrew on hub of flywheel and slide flywheel outward on compressor crankshaft until it

clears coils. Tighten setscrew.

(3) Refer to paragraph 4, step 2, table 4-2, for belt alignment.

(4) Install guard.

Step 3. Check for insufficient oil.

Check oil at oil level sight gage.