TM 5-4310-370-14

(1) Inspection check to see if stator assembly windings are dried out and/ or cracked and if stator assembly

wires are loose, frayed, split or disconnected. If any of these conditions exist, the stator assembly should

be removed and sent to the next level of maintenance to be repaired. (See APPENDIX B)

(2) Replacement replace stator assembly in accordance with procedures described in paragraph 5-2a.

f. Starter Switch Replacement

(1) If starter switch malfunctions, check all terminals to see that switch has been wired properly (figure 4-1) and

that connections are tight. Loose connections will cause starter switch to work improperly or not at all.

(2) Starter switch wiring procedures (figure 4-1).

WARNING

Disconnect unit from main power supply before servicing, replacing or repairing

parts of equipment, to avoid personal injury.

CAUTION

Push STOP button on starter switch and leave depressed.

NOTE

All following procedures must be performed by a qualified electrician.

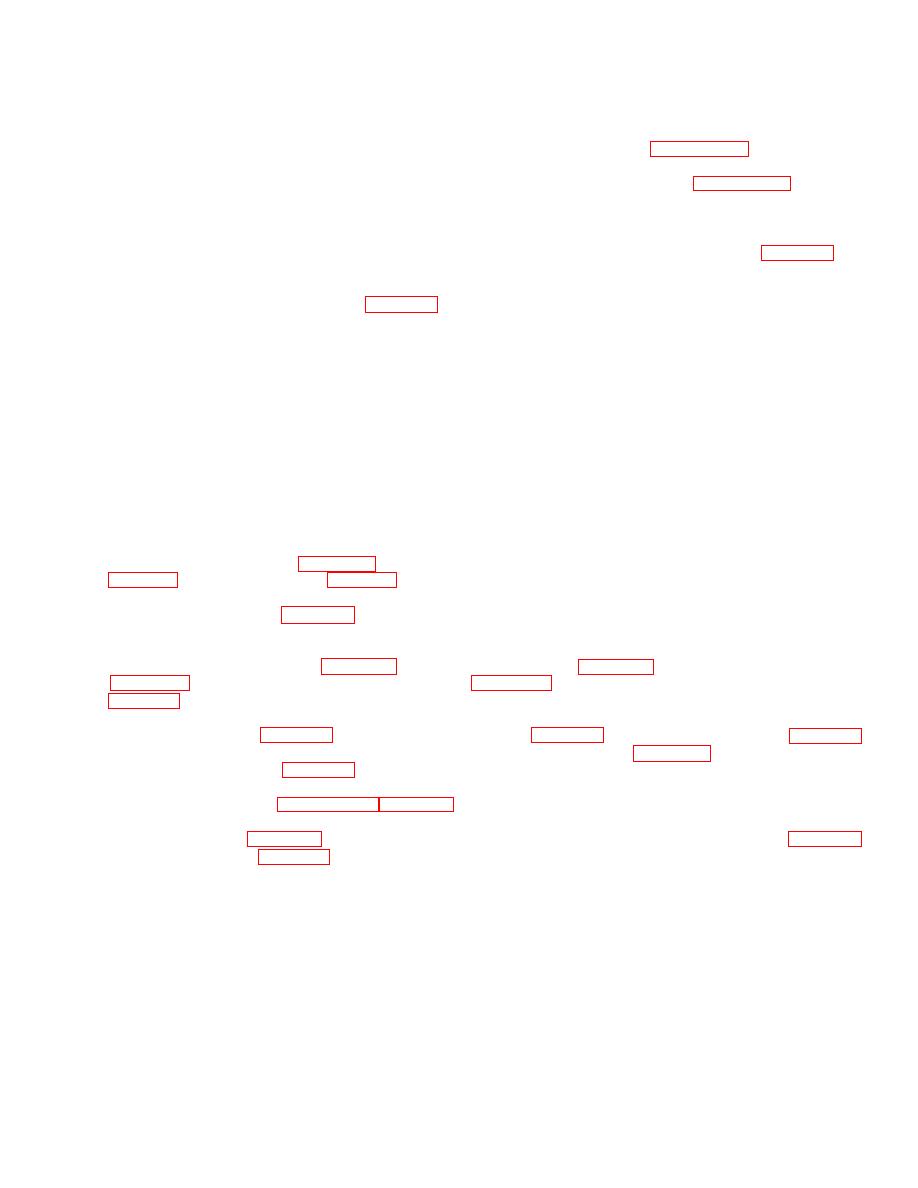

(a) Open front of starter switch (figure 5-2, item 1) and disconnect all electrical leads. Unscrew connection screws

(b) Remove ground wire nut (figure 5-2, item 4) to disconnect ground wire of motor cable from ground wire of main

power supply cable.

(c) Remove cable connection nuts (figure 5-2, item 5) from motor cable (figure 5-2, item 6), pressure switch cable

(figure 5-2, item 7) and main power supply cable (figure 5-2, item 8). Pull all cables from starter switch

(d) Remove starter switch (figure 5-2, item 1). Turn mounting bolts (figure 5-2, item 9), and mounting nuts (figure 5-2,

item 10) counter clockwise. Remove them from the mounting lockwashers (figure 5-2, item 11) and from air

receiver mounting bracket (figure 5-2, item 12).

(e) For wiring schematic, see paragraph 4-2, figure 4-1.

(f) Install starter switch (figure 5-2, item 1) on to air receiver mounting bracket. Replace mounting bolts (figure 5-2,

item 9) mounting nuts (figure 5-2, item 10) turning them clockwise.

5-12