TM 5-4310-375-14

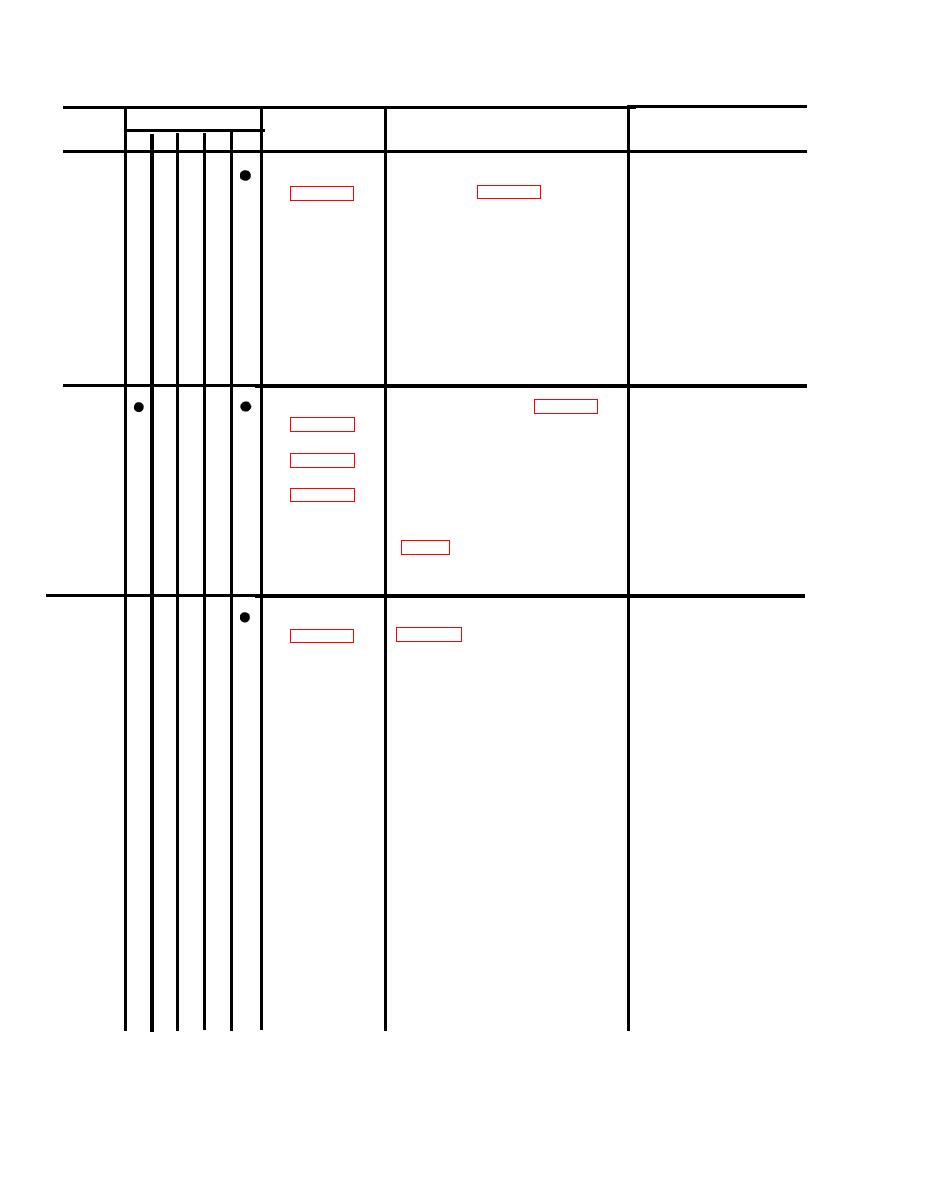

Table 2-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

EQUIPMENT IS NOT

ITEM TO BE

ITEM

lNTERVAL

W

D A

PROCEDURE

R E A D Y / A V A I L A B L E IF:

B

M

NO.

INSPECTED

Inlet air filter element is

Remove wing nut from top of inlet

Inlet air filter

10

damaged and no replace-

air falter (18, figure 2-1), lift off cap

(18, figure 2-1)

ment is available. Do not

and remove element. Clean element

operate compressor with-

in warm water and low-sudsing

household type detergent. Rinse

out element.

thoroughly in clean water and air

dry. Inspect element for breaks or

rupture; replace if any are found.

Install element, cap, and wing nut.

If unit is operated in an environ-

ment of dust or dirt, clean more

often than monthly.

Inspect belt guard (15, figure 2-1)

Belt guard or drive pulley

Belt guard

11

are damaged in any way.

for loose or missing mounting

(15, figure 2-1),

hardware and for breaks in guard

pulley

screen. Inspect drive pulley (19)

(19, figure 2-1),

for tightness on motor shaft and

and drive belts

for any damage to grooves that

(14, figure 2-1)

would damage drive belts. Check

drive belts for proper tension

(fig 2-3). Notify Organizational

Maintenance for repair or replace-

ment.

12

Examine the air compressor (13,

Air compressor

(13, figure 2-1)

dirt on cooling fins of intercooler

and aftercooler and fins of cylinder

head. Buildup of dirt will reduce

cooling effect of flywheel fan

blades. Clean the unit as needed.

WARNING

Dry cleaning solvent, Fed Spec

P-D-680, used to clean parts is

potentially dangerous to person-

nel and property. Avoid repeated

and prolonged skin contact. Do not

use near an open flame or excessive

heat. Flash point of solvent is 100

F - 138F (38C - 59C).

2-6