TM 5-4310-375-14

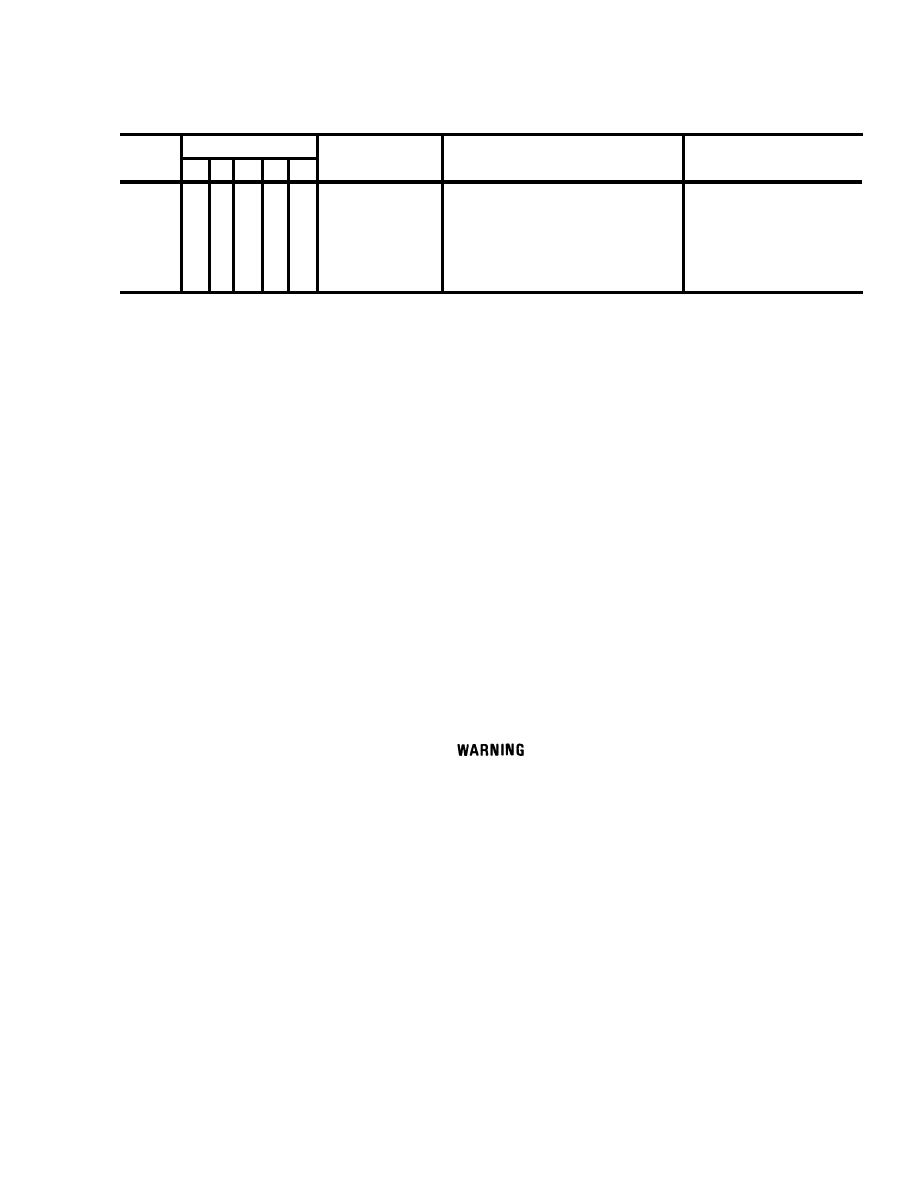

Table 2-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

EQUIPMENT IS NOT

ITEM TO BE

INTERVAL

ITEM

R E A D Y / A V A I L A B L E IF:

PROCEDURE

INSPECTED

DA

W

M

B

NO.

Clean unit using solvent, Fed Spec

P-D-680, or equivalent, to remove

oil and dirt from the compressor

and dry thoroughly.

Note:

Leakage definitions for operator/crew PMCS are as follows:

Seepage of fluid (as indicated by wetness or discoloration) not great enough to form drops.

Class I -

Leakage of fluid great enough to form drops but not enough to cause drops to drip from item being

Class II -

checked/inspected.

Leakage of fluid great enough to form drops that fall from the item being checked/inspected.

Class III-

CAUTION

Equipment operation is allowable with minor leakages (Class I or II).

Of course, you must consider the fluid capacity in the item/system

being checked/inspected. When in doubt, notify your supervisor.

When operating with Class I or Class II leaks, continue to check

fluid levels as required in your PMCS. Class III leaks should be

reported to your supervisor or Organizational Maintenance.

Section III. OPERATION UNDER USUAL CONDITIONS

2-5.

Assembly and preparation for use. The air compressor is shipped as a completely assembled unit. Openings

for forklift tines are provided for lifting unit from transporting equipment.

The forklift, or other lifting device, used for unloading or movement must

be capable of lifting a minimum of 1000 pounds (454 kgs).

a. Unloading. The unit can be unloaded from transporting carrier by using a lifting device or picked up with

a forklift. If lifting device is used, attach lifting cables under receiver tank and use spreader bars as necessary to

prevent unit from turning when lifted.

CAUTION

Do not lift unit by attaching cables to air compressor, motor, or belt guard

to prevent component damage.

(1) Remove all blocking and tie downs securing unit to carrier.

(2) Lift unit from carrier and transport to installation sight.

2-7