TM 5-4310-375-14

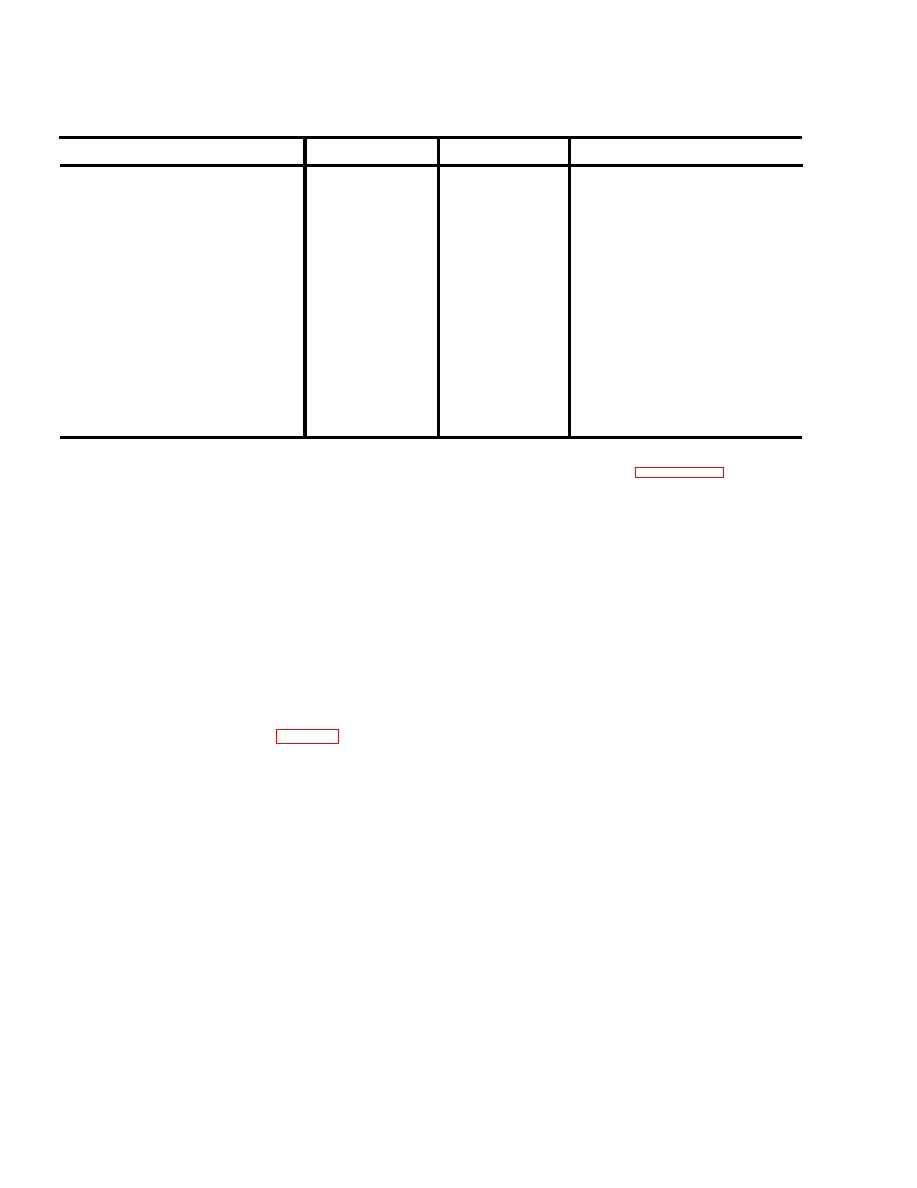

Table 3-1. Operator's Lubrication Table - Continued

1

LUBRICANT

CAPACITY

INTERVAL

LUBRICATION TASK

2. ELECTRIC MOTOR:

Two end plate lubrication fittings:

1 to 2 full strokes with grease gun.

6 months

Shell Alvania, or

Continuous duty, high ambient

equivalent

temperatures, dirty or moist lo-

cations, high vibration.

1 year (at be-

Shell Alvania, or

1 to 2 full strokes with grease gun.

Seasonal service, motor idle 6

equivalent

ginning of season.

months or more.

1 to 2 full strokes with grease gun.

2 years

Shell Alvania, or

Continuous duty, normal use.

1 to 2 full strokes with grease gun.

5 years

Shell Alvania, or

Service of 5,000 hours per year.

equivalent

1. Intends of lubrication tasks are based on normal hours of operation under usual conditions or as indicated for the electric motor. Reduce

interval if lubricants become contaminated or if equipment is operating under unusual conditions (Reference paragraphs 2-11 through 2-14.)

Section II. TROUBLESHOOTING

Introductory information.

3-3.

a. The troubleshooting table lists the common malfunctions which you may find during the operation or maintenance

of the air compressor unit or its components. You should perform the tests/inspections and corrective actions in the

order listed.

b. This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

3-4.

Troubleshooting table. Refer to table 3-2 for common malfunctions, test or inspection, and corrective actions

within the scope of the operator.

3-2