TM 5-4310-375-14

Table 3-2. Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. COMPRESSOR PUMPING OIL - Continued

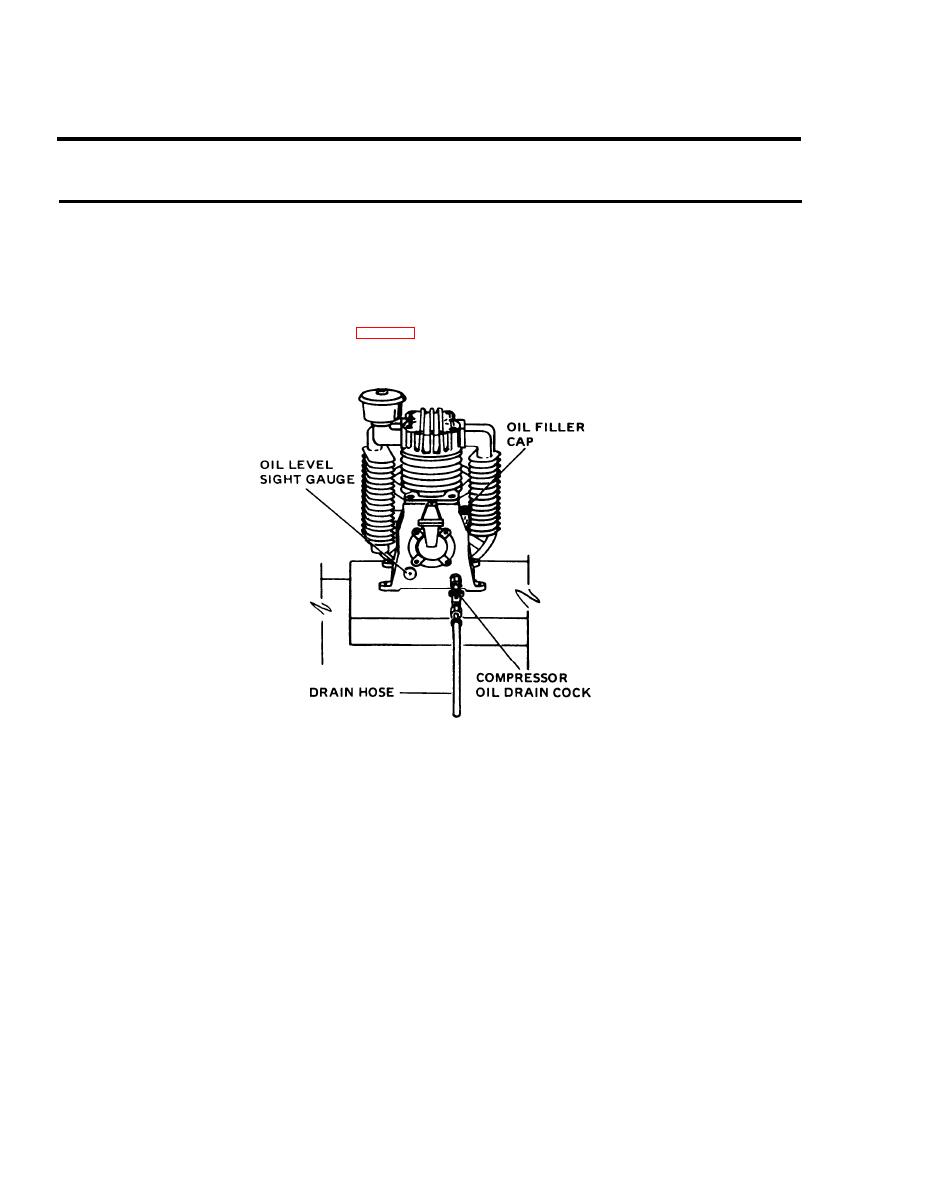

Step 2. Check oil level. View level of oil through sight gauge on air compressor frame.

If oil level is above center mark full indicator, open oil drain cock and drain oil to center mark Ievel.

Close drain cock. If oil level is below center mark level, remove oil filler cap and fill to proper Ievel in

accordance with lubrication table, table 3-1.

Figure 3-2. Air compressor service

2. MOTOR STARTING AND STOPPING FREQUENTLY

Step 1. Check air receiver tank for excessive condensate.

Drain the air receiver as follows:

a. Turn ON-OFF switch to OFF.

b. Open drain cock on bottom of air receiver tank to allow air and condensate to drain off.

Close drain cock.

c.

Turn ON-OFF switch to ON.

Step 2. Check for air leaks in piping.

a.

Make a solution of soapy water.

b.

Apply solution to all fittings and connections with a brush. A leak is indicated by bubbling of the

solution.

If a leak is found, notify Organizational Maintenance.

c.

3-4