TM 5-4310-375-14

WARNING

Drain air system before performing any maintenance. Open air receiver

drain cock.

4-22. Safety valve. When notified by operator/crew of either air compressor aftercooler or air receiver safety valve

leakage or that safety valve does not seat properly when inspected, unscrew the safety valve and replace. No repair is

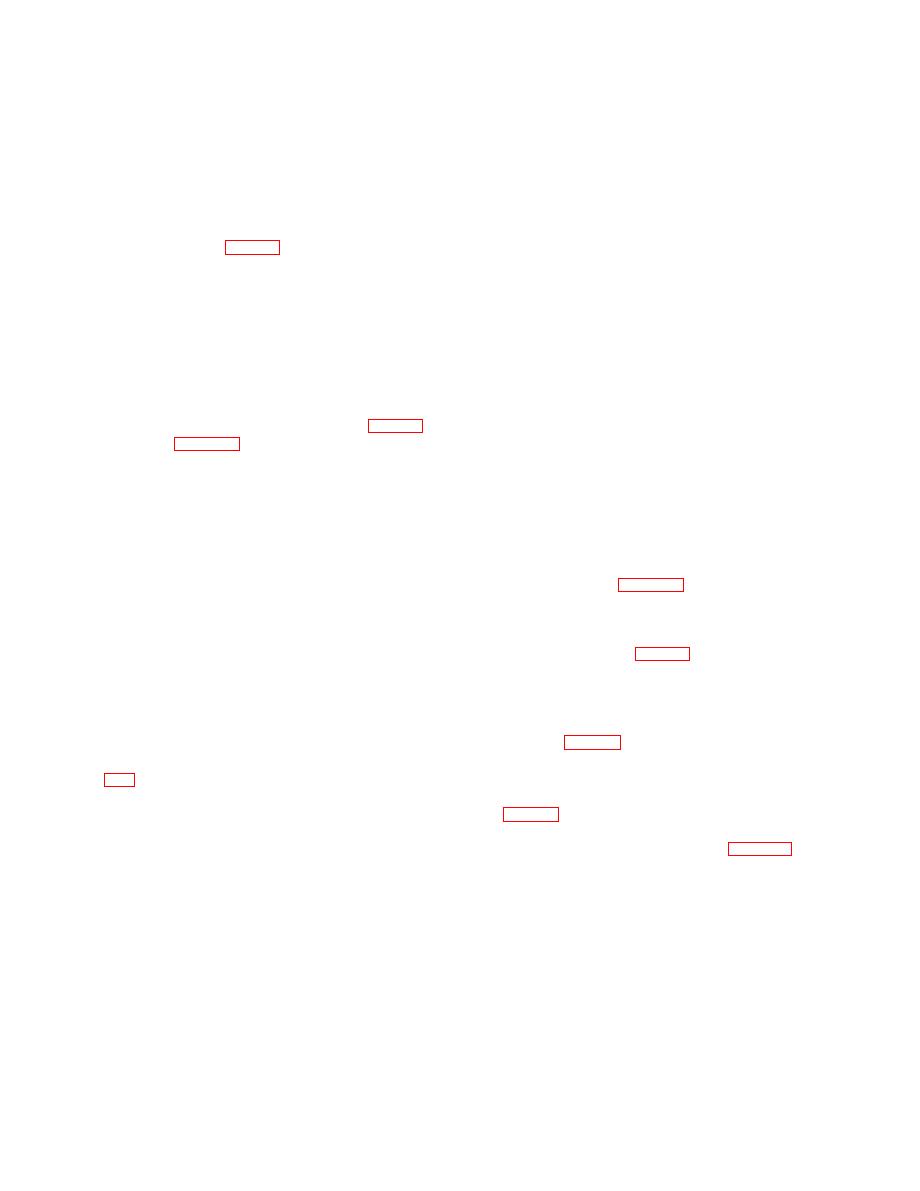

authorized. (Ref 13, fig 4-10.)

4-23. Check valve. Maintenance of check valve is as follows:

a. Inspection-Installed item. With air pressure in air receiver tank, apply a soapy water solution with a brush to the

check valve and connections. Observe for evidence of leakage indicated by bubbling of the solution. Check connections

for tightness; if secure and leakage is at check valve, replace the valve. Stop the unit and relieve air pressure from tank.

b. Removal/Replacement. Remove and replace check valve as follows:

(1) Disconnect air discharge tube (1, fig 4-10) from air compressor aftercooler outlet to check valve (refer to

para 4-30). Disconnect unloader tubing (9) from check valve and remove tubing connectors (2, 10) and

reducing bushing (3) from check valve (11).

(2) Unscrew and remove check valve (11) from air receiver tank.

(3) Install new check valve (11), install reducing bushing (3) and tube connectors (10, 2). Connect unloader

tubing (9) to connector (10) and air discharge tube (1) to connector (2).

(4) After replacement and installation, again check for leakage as instructed in para 4-23.a above.

4-24. Pressure gauge. Inspect, remove and replace the air pressure gauge as follows:

a. Inspection - Installed item. While unit is operating, observe air pressure gauge (14, fig 4-10) for proper

operation. Inspect for broken face. Apply soapy water solution with a brush around connection to tank and check for

leakage indicated by bubbling of solution. If face of gauge is broken, gauge does not operate properly, or leakage is

detected, the pressure gauge shall be replaced. Stop the unit and relieve pressure from air receiver tank.

b. Removal/Replacement. Unscrew and remove the air pressure gauge (14, fig 4-10) from air receiver tank. Install

a new gauge and position so gauge is in reading position when faced by operator. Then, again inspect as instructed in para

4-24.a above.

4-25. Air receiver drain cock. Maintenance of the drain cock (15, fig 4-10) is limited to replacement. When notified

by operator/crew of leakage or improper seating stop unit and drain receiver. Unscrew and discard the drain cock (15, fig

4-10) from bottom of air receiver tank. Install new drain cock (15) and check for leakage as instructed in para 3-12.b.

4-26. Air receiver. Maintenance of air receiver is as follows:

a. Inspection. Inspect air receiver for any dents and rusting. The air receiver is an ASME Pressure Vessel and shall

not be repaired. If inspection reveals dents that could cause rupture, notify direct support for replacement of air

receiver.

b. Painting. If inspection reveals rusting, clean, treat, and paint in accordance with Military Standard, MIL-T-704,

type A, lusterless, color Forest Green.

4-23