TM 5-4310-375-14

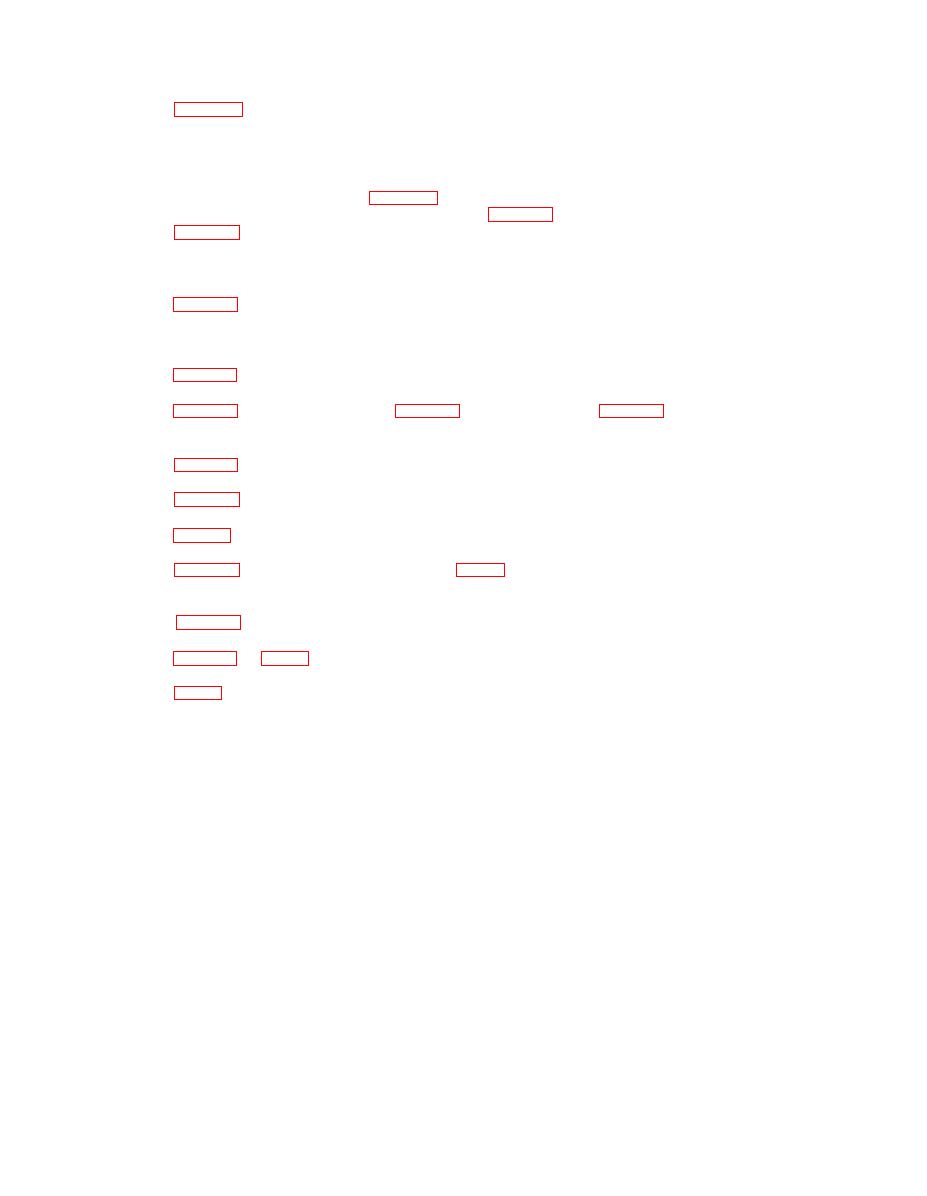

(9) Refer to figure 5-6 and remove close nipple (1), reducing bushing (2) and reducing bushing (3). Remove close

nipple (4) and reducing bushing (5). The square head pipe plugs (6, 7) need not be removed. Remove drain

cock (8) and reducing bushing (9) from air receiver tank (12). As necessary, remove four screws (10) and

identification plate (11).

b. Repair/Replacement. The air receiver tank (12, figure 5-6) is an ASME Pressure Vessel and shall not be repaired.

Replace a damaged air receiver tank (12). Paint the tank as instructed in para 4-26. Replace all damaged fittings of air

receiver tank group, figure 5-6.

c. Reassembly.

(1) Refer to figure 5-6 and install reducing bushing (9) and drain cock (8). If removed, install pipe plugs (7, 6).

Install reducing bushing (5) and close nipple (4). Install reducing bushing (3), reducing bushing (2) and close

nipple (1). Attach identification plate (11) with four screws (10).

(2) Refer to para 4-29 and install fittings and globe valve on air receiver tank.

(3) Refer to para 4-24 and install pressure gauge; para 4-23 and install check valve; para 4-22 and install safety

valve.

(4) Refer to para 4-18 and install air compressor assembly on air receiver saddle.

(5) Refer to para 4-30 and reassemble the air discharge piping from air compressor to receiver tank.

(6) Refer to para 5-6 and install air pressure switch.

(7) Refer to para 4-16 and install motor assembly. Refer to fig 2-3 and align motor drive pulley and compressor

pulley (flywheel).

(8) Refer to para 4-15 and install motor control box assembly.

(9) Refer to para 4-14 and fig 2-3 and install drive belts and adjust belt tension; then, install the belt guard.

(10) Refer to fig 1-2 and check all unit wiring connections.

5-20