TM 5-4310-376-14

112. FUNCTIONAL OVERVIEW - Continued

exhausted or you shut down the system.

gasoline engine, except power to drive the pistons is supplied by the engine.

continues to run. Controls operation according to rise and fall of air tank pressure.

Air Tank (4). Acts as reservoir for the compressed air and dampens pressure fluctuations

which you would get if you took the compressed air directly from the compressor.

1-13. COMPONENT DESCRIPTIONS

This paragraph describes operation of individual components.

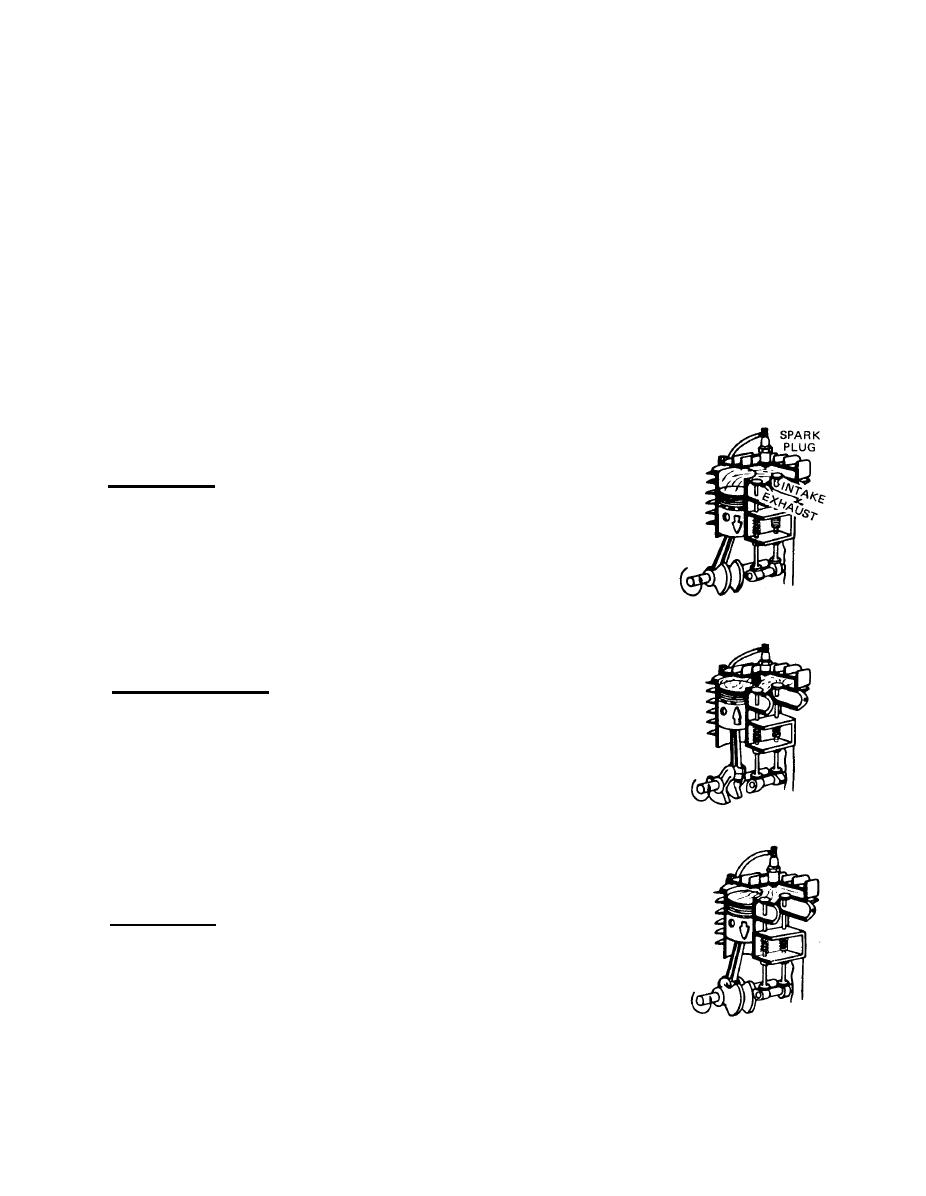

Intake Stroke

With exhaust valve closed and intake valve open, the piston

moves downward, creating a vacuum in the cylinder which draws

the air-fuel mixture into the cylinder through the open intake valve

into the space above the piston.

INTAKE STROKE

Compression Stroke

Then, the intake valve closes, and the piston moves upward on the

compression stroke. The air-fuel mixture becomes highly compres-

sed in the space left between the top of the piston and cylinder

head.

COMPRESSION STROKE

Power Stroke

The magneto sends hign tension current to the spark plug, the

spark occurs, igniting the mixture, and the force of the ex-

panding gases drives the piston down. This is a power stroke.

POWER STROKE

1-5