TM 5-4310-376-14

Table 4-2. Organizational Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

b. Defective stop switch.

Replace stop switch (para 4-31).

c. Sheared flywheel key (flywheel removed)

on flywheel side. Keyway in both fly-

wheel and crankshaft should not be dis-

torted.

Use only soft metal key as originally supplied.

Replace key/replace flywheel if keyway is distorted. Notify direct

support maintenance if crankshaft keyway is distorted.

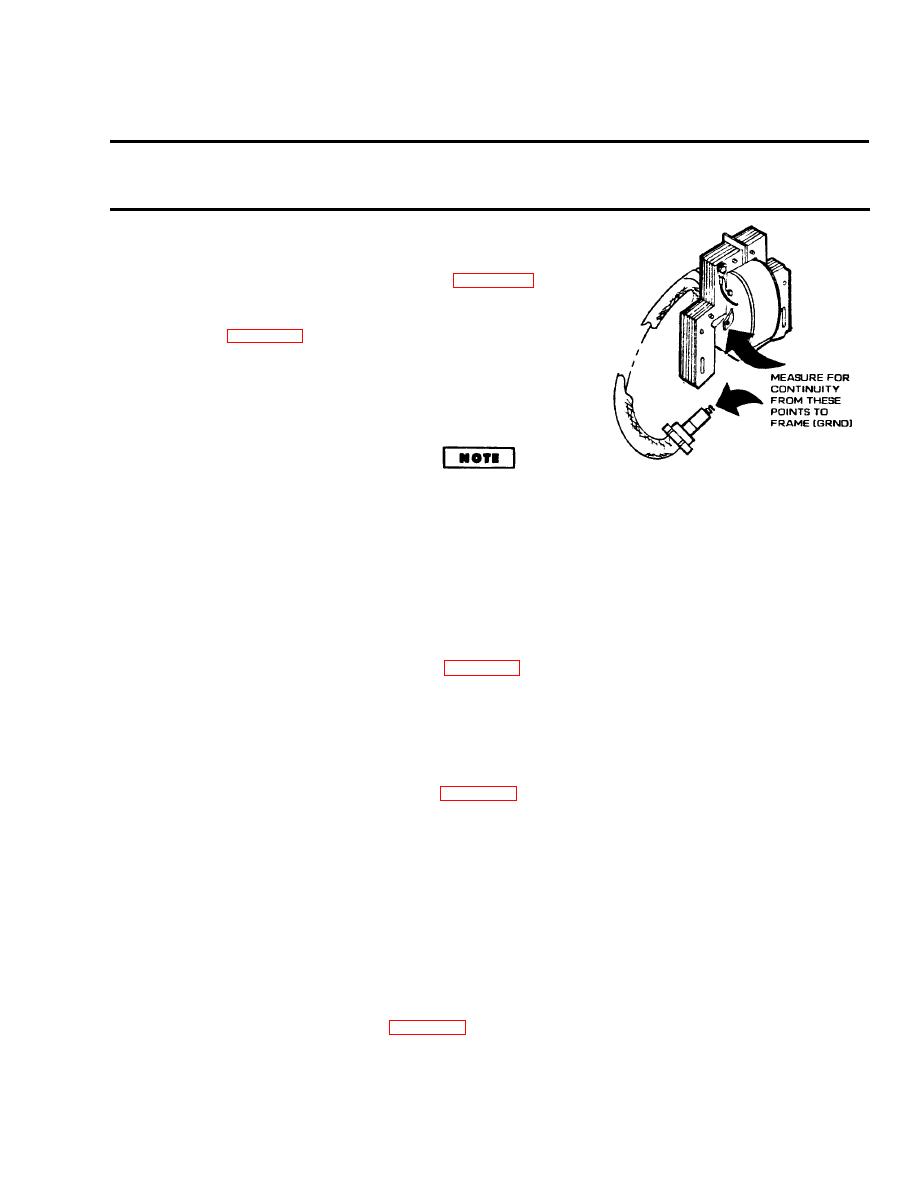

d. Armature failure. With ignition cable off of spark plug, use an ohmmeter and

measure for continuity (zero ohms) at points shown to frame. If no continuity,

armature is defective.

Replace armature (para 4-31).

Step 4. Check carburetion. With adequate clean fuel in tank, remove fuel pump

from carburetor, vacuum line attached, place in jar and pull starter; fuel

should flow freely.

Clean fuel line and carburetor with carburetor cleaner. Replace

in-line fuel filter (para 4-24).

a. Remove and inspect spark plug, if plug is wet, look for:

(1) Water in fuel.

Drain and refill fuel tank. Clean lines and carburetor with car-

buretor cleaner.

(2) Overcooking. Remove air cleaner; manually operate choke lever to see if

it is binding.

Sticking choke due to dirt, etc.; clean. Defective choke; replace

carburetor (para 4-28).

(3) Excessively rich mixture.

4-17