TM 5-4310-378-14

Q - Quarterly

M - Monthly

W - Weekly

A - After

D - During

B - Before

EQUIPMENT IS NOT

ITEM TO BE INSPECTED

READY/AVAILABLE IF:

PROCEDURE:

Cracked, frayed, or broken.

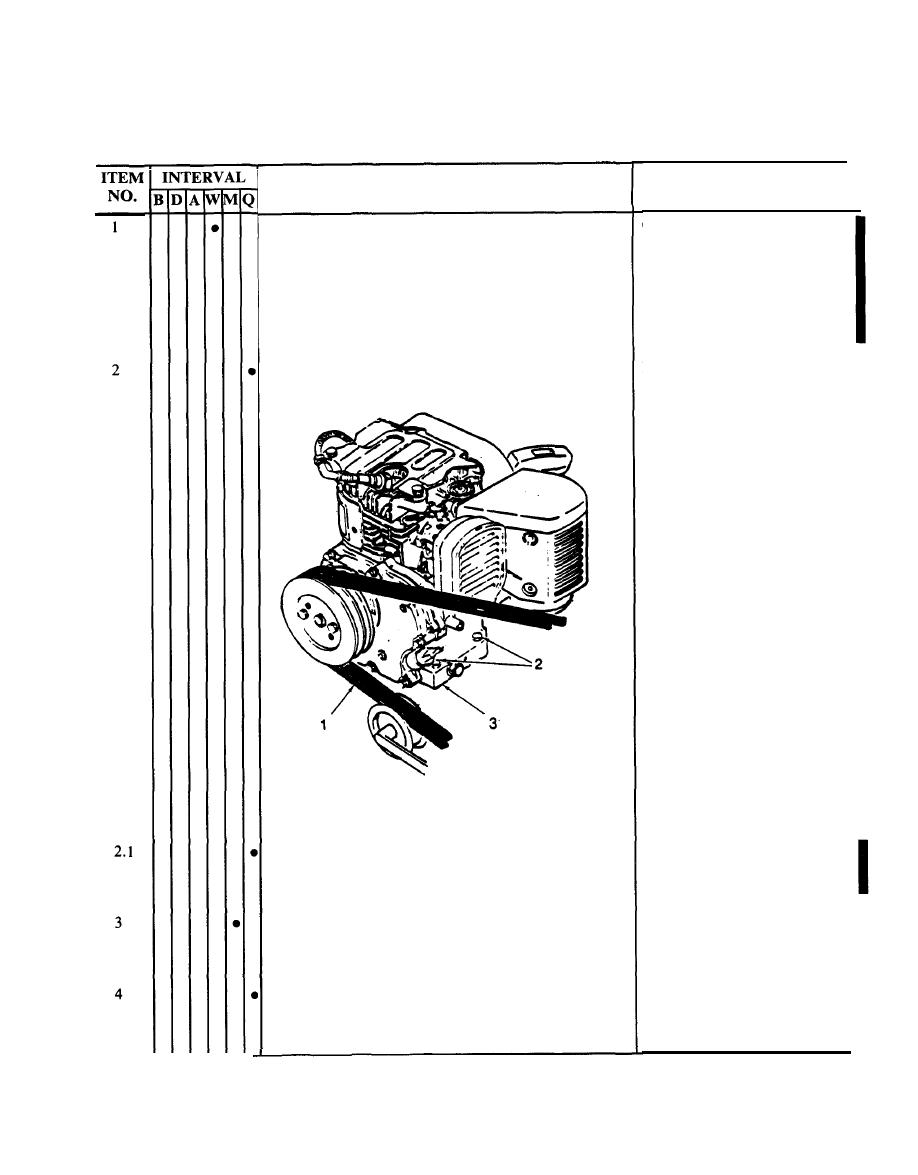

Drive Belts. Inspect for damage or broken belts.

With belt tension idler engaged, check belt (1) ten-

sion for 3/8 to 1/2 inch deflection at mid-point

between pulleys. To adjust belt tension, loosen the

four engine hold-down bolts (2) and move engine (3)

until belt tension is 3/8 to 1/2 inch. Tighten the four

hold-down bolts (2).

Loose or cracked.

Drive Pulley. Check for tightness of mounting and

cracks.

Loose or missing hardware.

Governor. Inspect governor mechanism outside of

crankcase for loose or missing springs, bolts, or nuts.

Inspect for dents, bent parts, or other damage.

Looseness or holes in gasket.

Engine Cylinder Head and Gasket. Inspect cylinder

head for secure mounting. Inspect gasket to ensure it

does not have any holes.

Loose or missing hardware.

Mounting Hardware. Check all hardware for secure

mounting and damage. Tighten all loose hardware.

Replace all damaged hardware.

Change 3 3-7