B - Before Operation

D - During Operation

A - After Operation

W - Weekly

Item

No.

Interval

Item To Be Inspected. Procedure:

Equipment Not

Ready/Available If:

B

D

A

W

TM 5-4310-385-13

Table 2-1. Operator's Preventive Maintenance Checks and Services (Continued)

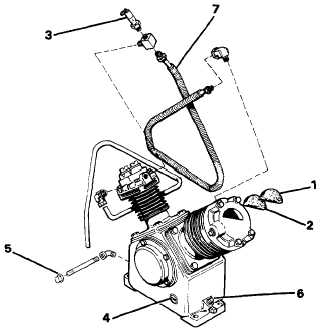

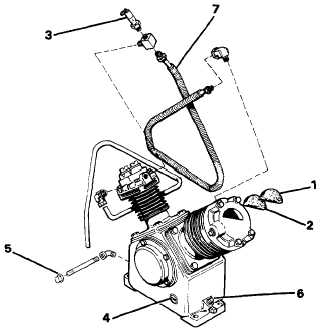

a. Inspect foam air filter (1) and felt silencer (2)

for dirt or debris. Clean with P-D-680 as necessary

and replace.

b. Inspect the safety interstage valve (3) during

Air release from valve

operation for air release. Air release indicates

during operation.

crimped intercooler or compressor damage.

c. Inspect oil level through sight glass (4).

Oil level is not seen

on sight glass.

d. Inspect drain plugs (5) and fill plugs (6) for

tightness.

e. Inspect intercooler (7) for cracks, dents, broken

Damaged intercooler

cooling fins, and secure fitting attachment.

may cause loss of air

pressure and over-

heating.

2-4