TM 5-4310-385-13

CHAPTER 3. UNIT MAINTENANCE INSTRUCTIONS

SECTION I. LUBRICATION INSTRUCTIONS

NOTE

These lubrication instructions are mandatory.

3-1. GENERAL. Lubrication of the air compressor is Iimited to servicing (changing) the oil in the air compressor unit.

WARNING

The air compressor must be stopped and power switch set to OFF position before

adding oil to prevent ejection of hot oil.

3-2. COMPRESSOR UNIT LUBRICATION.

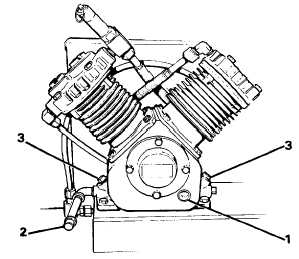

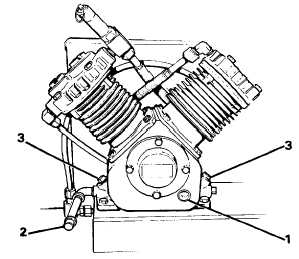

a.

Daily. Check the oil level in the sightglass (1). Add oil through the filler opening (3) to bring the level up to the full

mark. Refer to following table for proper viscosity.

b.

Quarterly. Remove the drain cap (2) and drain oil into appropriate container with at least a 1 pint (.5 L) capacity.

Install cap and pour 10 oz. (.3 L) of proper oil into either filler opening (3). Check oil after running following the oil

change.

Ambient

Oil Type

Above 90F (32C)

OE/HDO 40

32-90°F (0-32C)

OE/HDO 30

Below 32F (0C)

OE/HDO 20

Table 3-1. Proper Oil Viscosity

Compressor Lubrication

3-3. ELECTRIC MOTOR LUBRICATION. The electric motor ball bearings have been factory lubricated and sealed. No

grease fittings are present to lubricate bearings.

3-1