TM 5-4310-385-13

3-21. PRESSURE SWITCH. This task covers:

a. Initial Setup.

c. Inspection.

e. Installation.

b. Removal.

d. Cleaning.

f. Adjustment.

INITIAL SETUP.

a.

Tools. General Mechanic Automotive Tool Kit; T1 5180-00-177-7033.

b.

Materials/Parts. Compressed Air; Brush; Anti-Seize Tape.

c.

Equipment Condition. Main power disconnected; Compressor unit OFF; Air in tank discharged.

d.

General Safety Requirements.

WARNING

·

Observe all Warnings and Cautions.

·

Never wear loose Clothing or jewelry while inspecting or servicing equipment.

·

Beware of rotating shafts, pulleys and fans which could entrap personnel and

cause serious injury.

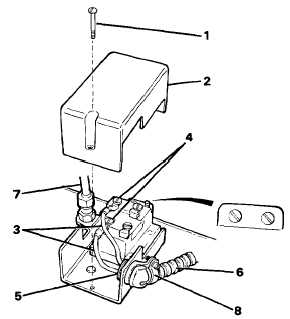

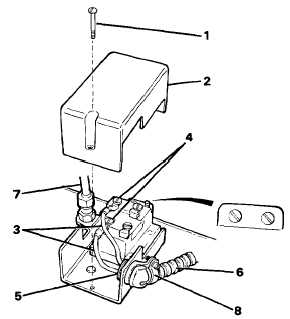

Pressure Switch

INSPECTION.

CAUTION

Use soap solution to check for air leaks at tank fittings only.

a.

With air pressure present in tank, inspect the pressure switch for air leaks using a soap and water solution.

b.

Check for air discharge from unloader valve (7) upon compressor shutdown.

c.

Inspect the switch contacts for burning or pitting. Replace the pressure switch if contacts are bad.

3-17