TM 5-4310-385-13

4-9. CRANKSHAFT BEARINGS. This task covers:

a. Initial Setup.

b. Disassembly.

c. Assembly.

INITIAL SETUP.

a.

Tools. General Mechanic Automotive Tool Kit T1 5180-00-177-7033; Basic Field Maintenance Automotive

Repair Shop Set, T2 4910-00-754-0705.

b.

Materials/Parts. Mineral Oil.

c.

Equipment Condition. Compressor disassembled (paragraph 4-7).

d.

General Safety Requirements.

WARNING

·

Observe all Warnings and Cautions.

·

Never wear loose clothing or jewelry while inspecting or servicing equipment.

·

Beware of rotating shafts, pulleys and fans which could entrap personnel and

cause serious injury.

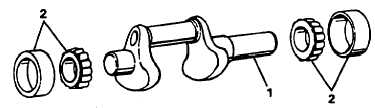

Crankshaft Bearings and Oil Seals

CAUTION

Crankshaft must be supported in a suitable fixture when removing or installing

bearings to prevent damage to crankshaft.

DISASSEMBLY.

a.

Clamp crankshaft (1) in a suitable fixture.

b.

Using a suitable bearing puller, remove bearings (2) from crankshaft (1).

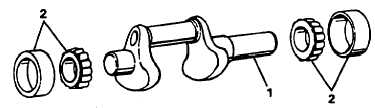

ASSEMBLY.

a.

Clamp crankshaft (1) in suitable fixture.

NOTE

Bearings should be immersed in mineral oil heated to a temperature of 6000F prior

to installing.

b.

Press bearings (2) onto crankshaft.

4-10