TM-5-4310-389-14

e.

Slacken the cylinder head bolts in quarter turn stages and diagonal sequence.

f.

Remove the cylinder head and pushrod tubes.

g.

Align the cylinders.

h.

Check/adjust piston crown clearance.

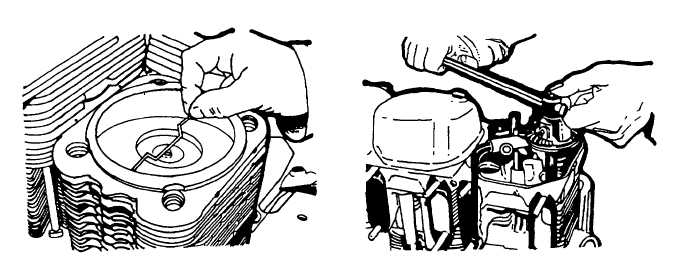

1. Apply grease to a piece of lead wire of 0.079-inch (2 mm) thickness and stick wire to piston crown (figure 4-28).

NOTE

Ensure piston is below TDC.

2.

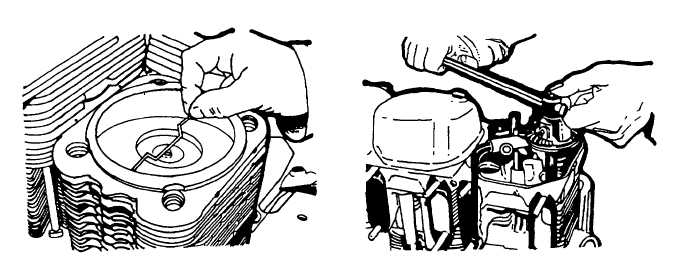

Mount cylinder head and insert securing bolts with washers.

3.

Preload bolts by above wrench through 22 lb-ft (30 Nm) (see tightening procedure, table F-1) and tighten through

one stage (45 degrees) with the aid of device No. 003-0500 (figure 4-29).

4.

Rotate crankshaft by one revolution (360 degrees).

5.

Unscrew bolts and remove head. Mark heads relative to cylinders.

6.

Take out wire and gauge at weakened point. Tolerance should be .039 to .047 inch (1.0 to 1.2 mm).

7.

Adjust clearance by using shims of 0.008 and 0.020-inch (0.2 mm and 0.5 mm).

Figure 4-28. Checking Piston Crown Clearance

Figure 4-29. Tightening Cylinder Head

Bolts with Tool 003-0500

4-58