TM-5-4310-389-14

NOTE

This is the recommended method of obtaining the correct clearance.

8

If the clearance is too small, remove cylinder and place the number of shims required below the cylinder.

NOTE

In the case of a distance of 0.024-inch (0.6 mm), instead of using several thin shims, use either one shim of

0.020-inch (0.5 mm) or one shim of 0.020-inch plus 0.008-inch (0.5 mm plus 0.2 mm), taking into consideration

the piston crown clearance with appropriate tolerance.

9.

If the clearance is too large, raise the cylinder and remove the surplus shims.

i.

Install head gasket (reusable gasket).

j.

Measure the length of head bolts. Renew those cylinder head studs that have stretched beyond the permissible

maximum limits 8.307-inch +.020-inch (211 mm ±.5 mm).

k.

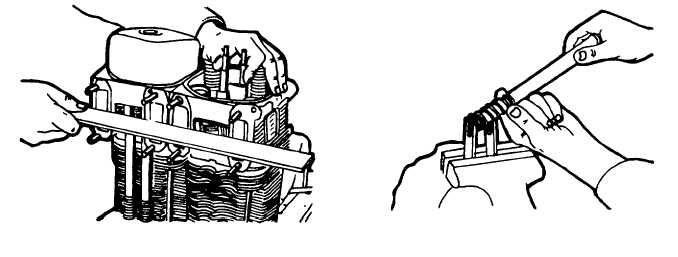

Assemble and hand-tighten the studs fitted with washers. Align the induction and exhaust flanges of the cylinder

heads without disturbing the alignment of the cylinders (figure 4-30).

1.

Tighten and torque down the head bolts in accordance with Appendix F.

m.

Install brass screw plugs with new gasket in the cylinder head. The tightening torque for the brass screw plugs is

60 to 65 lb-ft (80 to 90 Nm).

n.

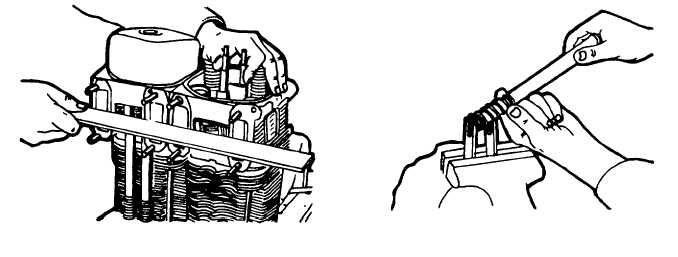

Assemble and tension the spring on the push rod tube (figure 4-31) using spring tensioning tool.

Figure 4-30. Aligning the Intake and

Figure 4-31. Assembling Spring onto

Exhaust Flanges

Push Rod Tube

4-59