TM-5-4310-389-14

j.

Compare the gap clearance of the piston rings with the values given in the specifications, table 4-4.

k.

Renew defective pistons together with piston pin and rings.

1.

When installing the piston rings, start by fitting the expander spring for the bevelled scraper ring in the bottom

groove.

REPLACE REPAIR

a.

Using piston ring expander No. 003-0496, assemble the piston rings in the following sequence:

NOTE

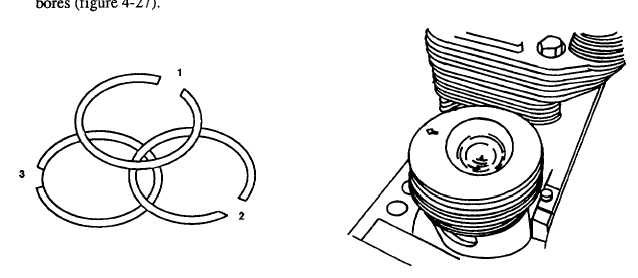

Place the rings so that the gaps are evenly spaced 120 degrees apart around the piston (figure 4-26).

1. (No. 3) Slotted, double-chamfered oil-control ring, chromium-plated.

2. (No. 2) Tapered compression ring, ferrox finished; install with face marked TOP upwards.

3. (No. 1) Top, double-trapezoidal compression ring, chromium-plated, TOP upwards.

b.

Fit the circlip in the boss that will face the cylinder that has not been dismantled.

c.

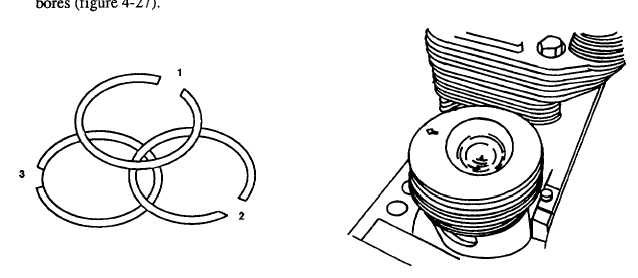

Heat piston with the piston heater No. 003-0414 [temperature about 176F (80C)]. Position the piston so that

the exhaust side (marked with an arrow on the piston crown) faces the push rod

Figure 4-26. Piston Ring Gap Replacement

Figure 4-27. Positioning Piston

4-55