TM-5-4310-389-14

d.

Pump the HP unit until fuel comes out of the overflow pipe. Slowly turn crankshaft in normal direction until only a

few droplets come out at intervals of 5 to 8 seconds.

e.

Ensure the Beginning of Delivery (FB) mark on the belt pulley agrees with pointer, so the fuel delivery timing is

correct.

f.

Turn off the high-pressure tester.

When setting beginning of delivery, turn the crankshaft in the direction opposite that of engine rotation through 90

degrees from the FB mark, and then in the direction of engine rotation until the FB mark on the V-belt pulley registers

with the retainer sleeve or setting indicator.

ADJUST

a.

Determining TDC with Setting Device.

1.

Remove no. I rocker chamber cover. (Cylinder closest to the flywheel.)

2.

Turn crankshaft until valves overlap, then give crankshaft another half turn.

3.

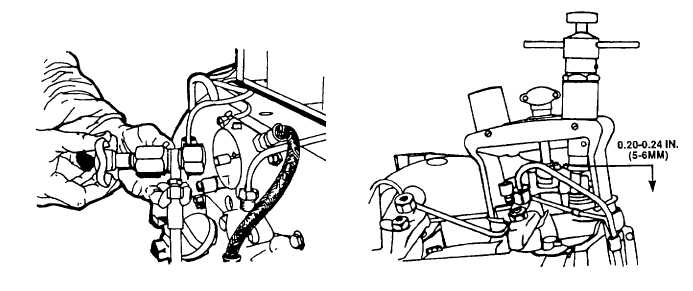

Mount setting device (003-0498). Using pressure screw of device, press down one rocker arm approximately

0.20 to 0.24-inch (5 to 6 mm) (figure 4-46).

4.

Fit dial gauge (003-0543) with preload.

5.

Secure graduated scale (003-0677) to V-belt pulley and fix pointer to dowel sleeve (figure 4-47).

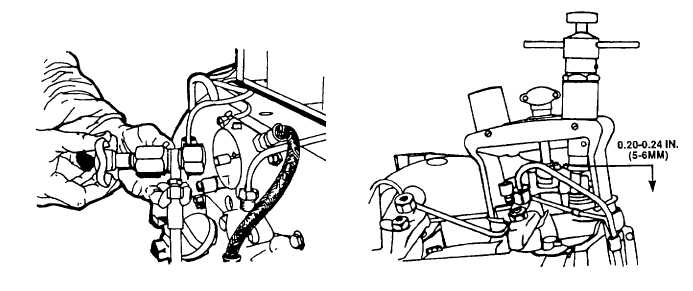

Figure 4-45. Connecting High-Pressure Tester

Figure 4-46. Setting the Adjusting Device

4-71