TM-5-4310-389-14

b.

Clean the cylinder head and inspect for external damage or cracks; renew, if necessary.

c.

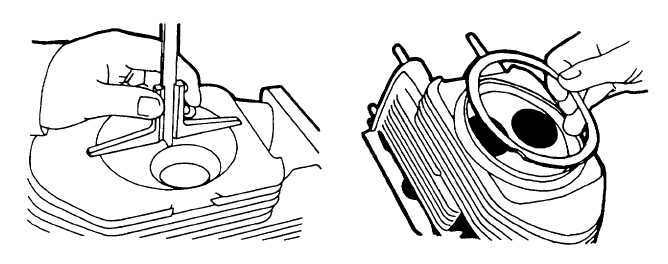

Check the cylinder head seating surface (figure 5-71). It must be flat and square. It can be refaced provided the

distance from the cylinder head sealing surface to the cylinder head crown is not less than the low limit given in the

specifications.

REPAIR

NOTE

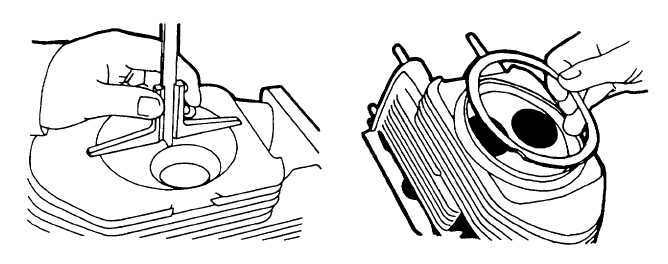

Measurements to be made with intermediate ring inserted.

a.

Slight damage to the cylinder head seating surface can be removed by grinding cylinder head on cylinder head

seating area. If more severely damaged, recut with plate mill No. 003-0426, or rework in the turning fixture No.

003-0621.

b.

Check cylinder head with fixture in lathe and align.

NOTE

While taking into consideration the permissible tolerance, remove only so much material as is

necessary for obtaining a perfect sealing surface.

c.

Ensure the intermediate ring is in good condition before placing it in the recess of cylinder head (figure 5-72).

Figure 5-71. Checking the Cylinder Head

Figure 5-72. Intermediate Ring

Seating Surface

5-44