TM-5-4310-389-14

d.

To determine the wear of the valve seat rings, take a new valve and measure the distance between the valve plate

and cylinder head seating surface (with intermediate ring placed in position). For valve recess, see specification

data in table 4-4.

e.

Renew valve seat rings (alternate methods).

1.

Using mandrel No. 003-1234: Install mandrel No. 003-1234 onto the cylinder head. Chuck cylinder head

with mandrel in lathe and turn out the worn rings.

2.

Install the drilling device No.003-0649 to a drilling machine for cutting out the valve seat rings. Place on the

cylinder head and insert the pilot pin with drilling bushes No. 003-0650.

3.

Drill out the valve seat rings by means of the hard metal special cutter No. 003-0652.

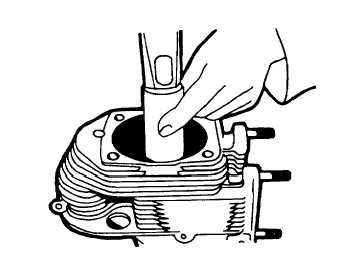

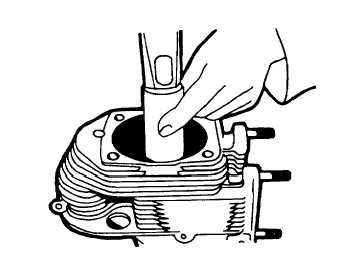

f.

Heat the cylinder head uniformly in a heating cabinet or oven to a temperature of 428F (220C). Slip the new ring

(available in oversizes) chamfered side first on the drift and seat it (use drift No. 003-0620 for exhaust valve,

respectively, figure 5-73).

Figure 5-73. Seating New Valve Ring

NOTE

To replace valve seat rings and valve guides, cylinder head should be heated up only once.

g.

Reface the seating rings that are not to be renewed. The maximum permissible distance from the center of the

valve head to the cylinder head seating surface should not be exceeded (use drift No. 003-0764, reseater with

holder for inlet and exhaust valve No. 003-0784).

5-45