TM 5-4310-393-14

WARNING

DEATH OR SERIOUS INJURY COULD OCCUR IF COMPRESSED AIR IS DIRECTED

AGAINST THE SKIN. DO NOT USE COMPRESSED AIR FOR CLEANING OR

DRYING UNLESS THE PRESSURE HAS BEEN REDUCED TO 30 PSI (2.06 BAR) OR

LESS. WHEN WORKING WITH COMPRESSED AIR ALWAYS USE CHIP GUARDS,

EYE PROTECTION, AND OTHER PERSONAL EQUIPMENT.

a.

Clean all parts in a shop parts washer if available, or with a clean cloth dampened with diesel fuel oil.

Use wire brush where necessary. Dry with low pressure compressed air.

C

Inspect.

1.

Inspecting the Parts.

a.

Inspect all parts for cracks, rust,

corrosion, and excessive heat damage.

b.

Inspect

for

accumulated

carbon

around injector seat In cylinder head.

FIGURE 5-21. ROCKER ASSEMBLY

c.

Measure rocker shaft (Figure 5-21, Item 1) diameter. If rocker shaft diameter is smaller than 0 7074

inch (17 974 mm), it must be replaced.

d.

Measure rocker bore bushing (2) inside diameter. If rocker bushing bore is greater than 0.7084 inch

(17 994 mm) replace bushing (2).

e.

Measure rocker (3) radius The radius must be 0.315 inch (8 mm). No flattening or brinnelling is

permitted on the rocker radius. If there is evidence of flattening, the rocker must be replaced

NOTE

When replacing the rocker (3) you must also replace the bushing (2). They are re-

placed as a set. The bushing (2), however, can be replaced separately.

2.

Inspecting the Valve Seats. Check valves, valve seats, and valve guides as follows:

a.

Check that the inside diameter of

each valve guide does not exceed 0 278 inch (7 059

mm).

b.

Check that the valve seat angle

does not exceed 45 degrees.

c.

Clean valves with diesel fuel and

wire brush and dry with low pressure compressed air.

d.

Inspect valves for warping, burning,

or other damage.

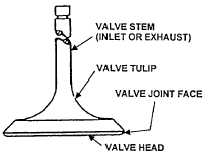

FIGURE 5-22. VALVE ELEMENTS

e.

Inspect valve tulips, faces, and heads for pitting, ridges, or cracks

f.

Check that each valve stem diameter is not less than 0.2736 in (6 95 mm).

5-20