TM 5-4310-393-14

g.

Check that each valve head diameter is not less than 1.193 inch (30.3 mm).

h.

Replace the cylinder head If any of the following conditions exist If the cylinder contact surface is

roughened, warped, and cannot be repaired; the valve seats are so worn that recutting is no longer possible, if contact

surface for cylinder head cover is rough or damaged; or if there are cracks between the valve seats

D.

Install.

1.

Installing the Inspected Components.

a.

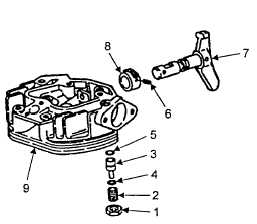

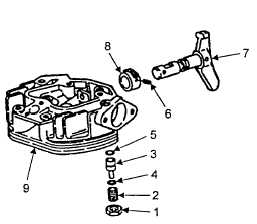

Install pinion (Figure 5-23, Item 8) In

cylinder head (9). Gear teeth go toward the inside and

no-teeth area of the pinion at the bottom.

b.

Insert

decompression

shaft

(7)

through cylinder head (9) and into pinion (8).

c.

Align

holes

in

pinion

(8)

and

decompression shaft (7) d Install roll pin (6).

e.

Install new preformed packing (5) on

pin (3)

FIGURE 5-23. DECOMPRESSION MECHANISM

f.

Install 10 spring plates (4) on pin (3). The spring plates must be installed In five sets with concave

sides together to create spring action.

g.

Install pin (3) with assembled preformed packing (5) and spring plates (4) into cylinder head (9).

h.

Rotate decompression shaft (7) to horizontal position.

I.

Install threaded pin (2) and tighten until snug Shaft must be free to turn but not move with vibration.

j.

Secure lock nut (1).

CAUTION

Do not scratch the cylinder head

sealing surface. Scratches will cause

poor sealing of cylinder head and

cylinder surfaces.

k.

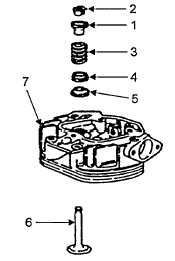

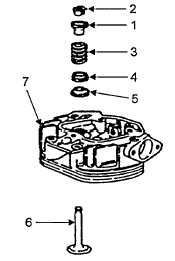

Insert valve (Figure 5-24, Item 6)

into cylinder head (7).

I.

Install cap (5), washer (4), valve

spring (3) and cup (1).

m.

Press down cup (1) and install

collets (2)

FIGURE 5-24. REASSEMBLE VALVES

5-21