TM 5-4310-393-14

E.

Adjust.

CAUTION

Too small a clearance will damage piston, cylinder head, and valves. Too large a

clearance will result in difficult starting.

1.

Adjusting the Cylinder Head (Bumping) Clearance.

a.

Crank engine to dead center position.

b.

Ensure cylinder head surface is free of dirt, carbon, or sealing material residue and place cylinder

head gasket onto cylinder head.

c.

Use a dial indicator to establish true top dead center of the piston.

d.

Place a straight edge across the top of the cylinder and measure the distance between the top of the

cylinder gasket and the top of the piston with a feeler gauge.

e.

Ensure that the bumping clearance is between 0.0216/0.0255 inch (0.549/0.648 mm).

NOTE

Gaskets come in various thickness. If you have a choice between two gaskets, it is

best to use the thickest one. Use only one gasket with the required thickness.

2.

Adjusting the Pushrods.

a.

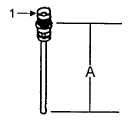

Adjust

complete

pushrod

(Figure 5-30, Item 1) so dimension "A", measured from

bottom of pushrod to the top of the collar, equals

5.8189/5.8268 inch (147.8/148.0 mm). This adjustment

Is required for proper engagement of complete pushrod

with pinion on decompression shaft.

3.

Adjusting the Tappet Clearance.

a.

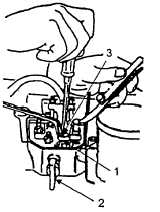

Put decompression lever (1) in

START position. (Figure 4-3).

b.

Turn engine clockwise when facing

throttle control lever until compression resistance can be

felt.

c.

Check clearance between rocker

and valve stem with a feeler gauge. Tappet clearance

cold should be 0.004 Inch (0.10 mm). To correct

clearance, loosen nut (2).

d.

Adjust screw (Figure 5-31, Item 3)

with a screwdriver until feeler gauge can be pulled

between rocker and valve stem with very slight

resistance after nut (2) has been tightened

FIGURE 5-30. PUSHROD

FIGURE 5-31. TAPPET ADJUSTMENT

5-24