TM 5-4310-393-14

b. Vent any residual pressure from the system by opening and then closing the manual drain valves on

separators and purge valve of the purification system

1.

Open the filler cap slowly, allowing any residual pressure to vent from the crankcase.

2.

Remove the cap/dipstick from the oil filler neck.

3.

Place a suitable oil drain pan beneath the drain plug at the back of the unit.

4.

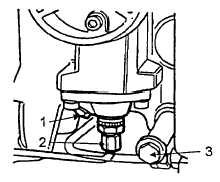

Remove the oil drain plug from the compressor, (figure 3-9, item 3).

5.

Allow the warm oil to totally drain.

6.

Reinstall the oil drain plug.

7.

Remove the oil drain pan. Dispose of the used oil in accordance with current instructions for waste oil

disposal.

CAUTION

To avoid damage to the compressor, do not mix type or viscosity grades of oil. Do not over-fill.

c.

To fill with oil, pour 1.5 quarts of oil slowly into the oil filler neck. Wait five (5) minutes after filling, check oil

level (A above), if necessary add oil, reinstall the filler cap, then start the compressor unit.

d.

Check the operation of the oil pump. It is working properly if no bubbles are visible in the oil pressure

regulating valve sight glass. (See figure 3-10, item 3).

e.

Vent the pump if bubbles are visible, (2

below).

2.

Venting the Oil Pump.

a.

Shut down the compressor and vent the

crankcase.

b.

Slowly loosen the tube nut (Figure 3-9,

Item 2).

c.

Turn the compressor by hand until

bubble-free oil emerges from the fitting.

d.

Tighten the tube nut.

FIGURE 3-9. COMPRESSOR OIL PUMP AND DRAIN PLUG

C.

Adjust.

1.

Adjusting the Oil Pressure Regulating Valve.

NOTE

The compressor must be in operation. The oil pressure regulator is mounted on

the third stage cylinder and adjusted to 850 psi (60 bar) (Normal operating range is

800 psi to 900 psi). The oil pressure is set at the factory and usually does not

require adjustment.

3-17