TM 5-4310-393-14

a.

Disconnect the inlet and outlet tubes from

the filter head using a n open end wrench.

b.

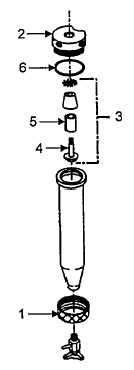

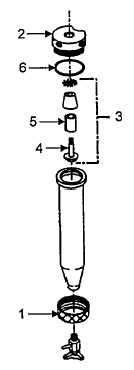

Unscrew threaded collar (1). Remove

filter head (2) and sintered filter assembly (3). Remove

the center screw (4) to remove the filter element (5).

Inspect O-ring (6) for damage. Replace if necessary.

2.

Cleaning the Sintered Filter (5).

a Clean the element using hot soapy

water. Blow dry with compressed air.

3.

Reassembling the Intermediate Filter.

a.

Coat the threads and O-ring and the

threads of the filter element with a thin coat of halo

carbon grease.

b.

Dry the inside of the filter housing with a

clean cloth and check for corrosion before reinstalling

the filter element. If excessive corrosion is found, refer

to Unit Maintenance.

FIGURE 3-12. INTERMEDIATE FILTER

3-15. DIESEL ENGINE.

This task covers' A Inspect B. Service

Tools:

Materials/Parts

Tool kit, General Mechanic's Set

Oil

Cloth, Lint-free NSN 7920-00-044-9281

Copper Gasket PIN 50001500

Equipment Conditions:

Engine Shut Down After Running

A.

INTRODUCTION. This paragraph covers maintenance procedures at the operator level for the diesel engine.

3-21