TM 5-4310-451-14

5-73.

ALTERNATOR TESTING AND REPAIR (Con’t).

6.

Inspect rotor assembly slip rings for scoring, wear, and pitting.

(a)

If slip rings are dirty, clean with 400 grit or finer abrasive cloth. Spin rotor assembly and hold abrasive cloth

against slip rings until clean.

(b)

If scored, worn, or pitted, turn slip rings in lathe and remove only enough material to make slip rings smooth

and round. Finish with 400 grit or finer abrasive cloth. Clear away all dust.

7.

Inspect slip ring end of rotor shaft for overheating and scoring. If there are signs of overheating or scoring, replace

slip ring end frame bearing and rotor assembly.

8.

Inspect drive end frame bearing for damage in accordance with TM 9-214. Inspect felt seal in retainer for

damage. If drive end frame bearing or felt seal is damaged, replace both bearing and felt seal.

9.

Inspect engine stator and rotor assembly winding for burned insulation. Burned insulation appears as a dark or

blackened wiring. A strong burned odor will be apparent. Replace engine stator or rotor assembly if either looks

burned.

10.

Inspect engine stator terminal connector for corrosion and breaks. If corroded or broken, replace engine stator.

11.

Inspect windings on engine stator for chipped insulation. Repair engine stator insulation with insulating varnish if

possible. Replace engine stator if insulation cannot be repaired with insulating varnish.

e.

COMPONENT TEST

1.

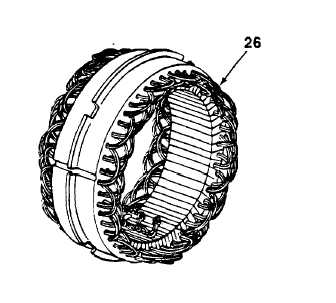

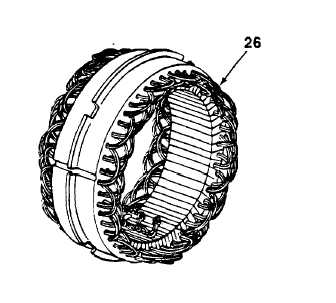

Using test light or ohmmeter, check continuity

between each engine stator lead terminal with

scale of 200 ohms or less. If there is no

continuity, replace engine stator.

2.

Using test light or ohmmeter, check continuity

between each engine stator lead and engine

stator (26) frame. If continuity Is not infinite,

replace engine stator.

3.

Connect voltmeter and fast charger to 12-volt

battery.

TA705160

5-294