TM 5-4310-451-14

5-73.

ALTERNATOR TESTING AND REPAIR (Con’t).

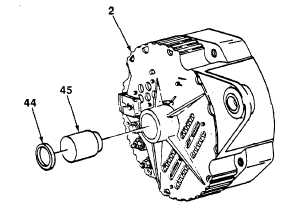

25.

If damaged, remove and discard roller bearing

and plug assembly (45) and seal (44) from slip

ring end frame (2).

d.

CLEANING AND INSPECTION

WARNING

Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never

exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to

avoid Injury to personnel.

1.

Clean all electrical parts with a clean rag and compressed air to clear away loose particles.

WARNING

Dry cleaning solvent, P-D-680, Is toxic and flammable. Always wear protective goggles and

gloves, and use only In a well-ventilated area. Avoid contact with skin, eyes, and clothes, and DO

NOT breathe vapors. DO NOT use near open flame or excessive heat. The solvent’s flash point Is

1000F-138°F (38°C-59°C). If you become dizzy while using cleaning solvent, Immediately get fresh

air and medical help. If solvent contacts eyes, Immediately wash your eyes and get medical aid.

2.

Clean all metal parts with dry cleaning solvent. Dry with clean rags.

3.

Inspect electrical brush holder assembly for damage. Replace electrical brush holder assembly if damaged or If

brushes are worn to a length of X in. (9.53 mm) or less. If brushes are to be reused, clean with soft dry cloth.

4.

Inspect two capscrew and insulator assemblies for damage and missing insulators. Replace if insulators are

damaged or missing.

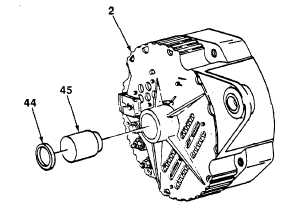

5.

Inspect slip ring end frame roller bearing and plug assembly for damage In accordance with TM 9-214. Inspect

bearing for Inside diameter of 0.9839-0.9843 in. (24.9911-25.0012 mm) and outside diameter of 2.4404-2.4409 in.

(6.19862-6.19989 cm). Replace bearing if damaged, or if grease supply is used up, or if measurements are not

within specified limits.

TA705159

5-293