TM 5-4310-451-14

5-75.

ENGINE STARTER REPAIR.

This Task Covers:

a. Disassembly

c. Assembly

b. Cleaning and Inspection

Initial Setup:

Equipment Conditions:

Materials/Parts:

•Engine starter removed (see paragraph 4-53).

•Adhesive (Item 1, Appendix E)

•Engine starter solenoid removed (see paragraph

•Abrasive cloth (Item 9, Appendix E)

5-77).

•Lubricating oil (Item 28, Appendix E)

Tools/Test Equipment:

•Rags (Item 35, Appendix E)

•General mechanic's tool kit

•Dry cleaning solvent (Item 38, Appendix E)

•Field automotive shop set

•One locknut

•Automotive fuel and electrical system shop set

•One oil seal

•One retaining ring

General Safety Instructions:

•Three gaskets

•Dry cleaning solvent is flammable and must not be

•Three wicks

used near open flame. Use only in a well-ventilated•Five preformed packings

area.

•Eleven lockwashers

•Compressed air used for cleaning purposes should

never exceed 30 psi (207 kPa).

a.

DISASSEMBLY

1.

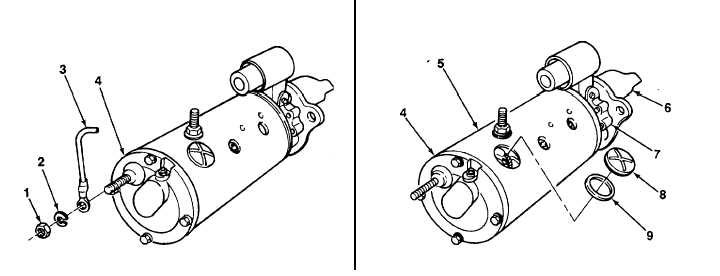

Remove nut (1), lockwasher (2), and electrical lead (3) from end cap (4). Discard lockwasher.

2.

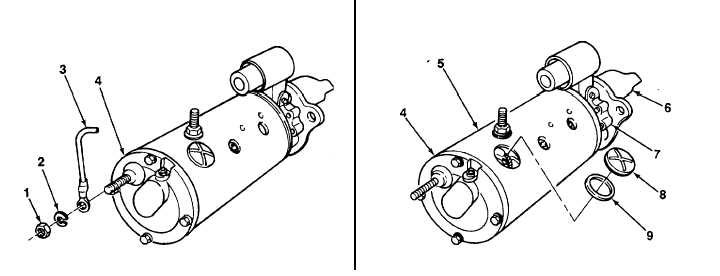

Mark end cap (4), field frame (5), lever housing (7), and drive housing (6).

3.

Remove two Inspection plugs (8) and gaskets (9) from field frame (5). Discard gaskets.

TA705173

5-307