TM 5-4310-452-14

5-8. CYLINDER REPLACEMENT.

This Task Covers:

a. Removal

b. Installation

Initial Setup:

Equipment Conditions:

Materials/Parts:

• Engine off.

• Petrolatum (Item 10, Appendix E)

• Battery cables disconnected (see paragraph

• Lead wire (Item 13, Appendix E)

4-57).

• Shims (as required)

• Cylinder head removed (see paragraph 5-7).

• Spacer ring (as required)

Tools/Test Equipment:

• General mechanic's tool kit

• Micrometer

• Ring compressor

a.

REMOVAL

NOTE

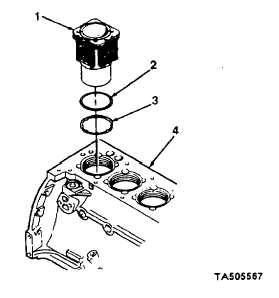

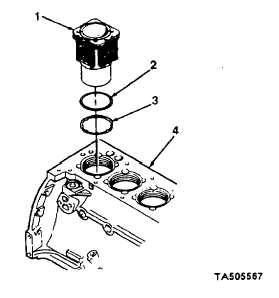

Use this task to remove any one of 4 cylinders. No. 1 cylinder shown.

1.

Using 36 mm socket and breaker bar, turn crankshaft until piston in cylinder (1) to be removed is at bottom dead

center.

CAUTION

To prevent damage to piston or piston rings, do not allow piston or connecting rod to knock

against engine block when removing cylinder.

2.

Lift cylinder (1) out of engine block (4).

3.

Remove spacer ring (3) and shim (2) from cylinder

(1). If cylinder is defective and being replaced,

discard spacer ring and shim.

b.

INSTALLATION

1.

Apply a thin coat of petrolatum on spacer ring (3)

and shim (2). Install shim in groove in cylinder (1)

and install spacer ring on cylinder.

2. Using 36 mm socket and breaker bar, turn crankshaft

until piston in cylinder (1) to be installed is at top

dead center.

3.

Using ring compressor, compress piston rings.

4.

Install cylinder (1) in place over piston and on

engine block (4) so that inlet and exhaust port are

facing left side of compressor unit.

5-21