TM 5-4310-452-14

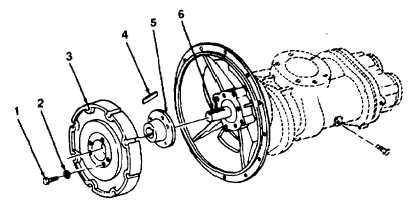

5-38. COMPRESSOR COUPLING AND MOUNTING REPAIR.

This Task Covers:

a. Disassembly

b. Assembly

Initial Setup:

Equipment Conditions:

Materials/Parts:

• Compressor removed from engine (see para-

• Sealing compound (item 12, Appendix E)

graph 5-35).

Tools/Test Equipment:

General Safety Instructions:

• General mechanic's tool kit

• Compressed air used for drying or cleaning

purposes must not exceed 30 psi (207 kPa).

a. DISASSEMBLY

1.

Remove 3 screws (1) and washers (2) from coupling (3) and bushing (5).

2.

Install 2 screws (1) in threaded jack screw holes in coupling (3). Tighten screws until coupling is free of bushing

(5).

3.

Remove bushing (5) and key (4) from shaft (6).

4.

Remove screws (1) from coupling (3).

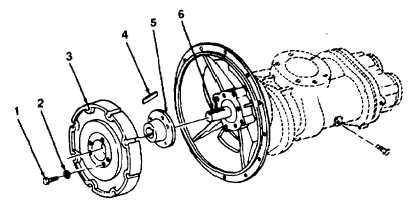

b. ASSEMBLY

1.

Install key (4) in keyway of shaft (6). Position bushing (5), flange end first, on key and shaft.

2.

Position coupling (3) on bushing (5).

3.

Apply a light coat of sealing compound on threads of 3 screws (1). Install, but do not tighten, 3 screws and

washers (2) in coupling (3).

TA505613

5-93