TM 5-4310-452-14

Section III. OPERATOR MAINTENANCE PROCEDURES

Paragraph

Page

Number

Title

Number

3-4

Air Cleaner Cleaning .......................................................................................................... 3-6

3-5

Engine Cooling Fan, Cooling Fins, and Oil Cooler Cleaning ............................................... 3-7

3-6

Fuel/Water Separator Servicing ......................................................................................... 3-9

3-7

Compressor Oil Cooler Cleaning ........................................................................................ 3-9

3-8

Parking Brake Adjustment .................................................................................................. 3-10

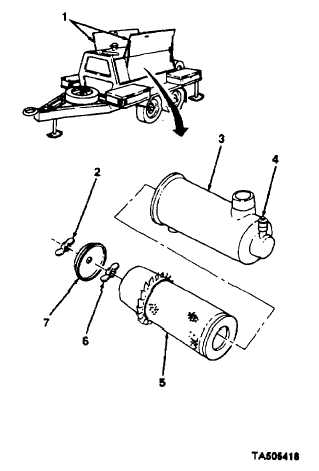

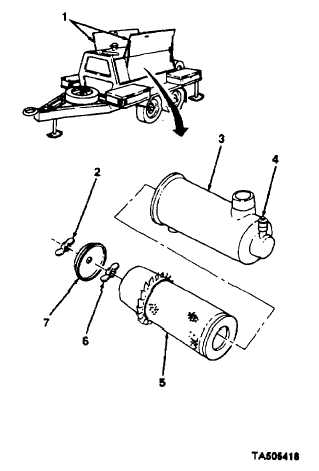

3-4. AIR CLEANER CLEANING.

NOTE

Engine and compressor air cleaners are cleaned the same.

a.

Removal.

(1)

Open left and right door assemblies (1).

(2)

Remove wingnut (2) and cover (7) from

air cleaner body (3).

(3)

Remove wingnut (6) and filter element (5)

from air cleaner body (3).

b.

Cleaning.

WARNING

Compressed air used for cleaning or

drying purposes, or for clearing

restrictions, should never exceed 30

psi (207 kPa). Wear protective

clothing

(goggles/shield,

gloves,

etc.) and use caution to avoid injury

to personnel.

(1)

Direct

compressed

air

through

filler

element (5) in opposite direction of normal air flow.

Using a gun, move 'up and down while directing

compressed air through filter element,

(2)

Using a light inside filter element (5),

visually inspect for tears or holes. If filter element has

tears or holes, or is contaminated with dry or greasy dirt

or oil, it must be replaced. Notify your supervisor.

(3)

Clean air cleaner body (3) with rag (Item

11, Appendix E), Inspect air cleaner body for cracks,

breaks. or dents. If damaged, notify your supervisor.

3-6