line leading to the pump to prevent conden-

3-12. Drive Sheave

sate freezeup. The alcohol dispenser is equip-

Keep the drive sheave (4, fig. 3-7) free from

ped with an eight-ounce capacity metal bowl

dirt, grease and foreign matter at all times to

and a needle valve which controls the flow of

prevent belt slippage and damage to belts or

alcohol.

drive sheave.

b. Service (fig. 2-8).

(1) Shut down the unit (para 2-12).

(2) Remove plug handle and fill with

alcohol. Reinstall handle.

(3) Start engine (para 2-11).

(4) During operation, inspect sight gauge

frequently and refill when necessary.

(5) Open needle valve to increase and

close to decrease flow of alcohol.

3-10. Air Compressor

a. Oil Level. To check the oil level in the

compressor, remove oil filler plug (fig. 3-4).

Oil level should be even with the bottom

threads of the filler plughole.

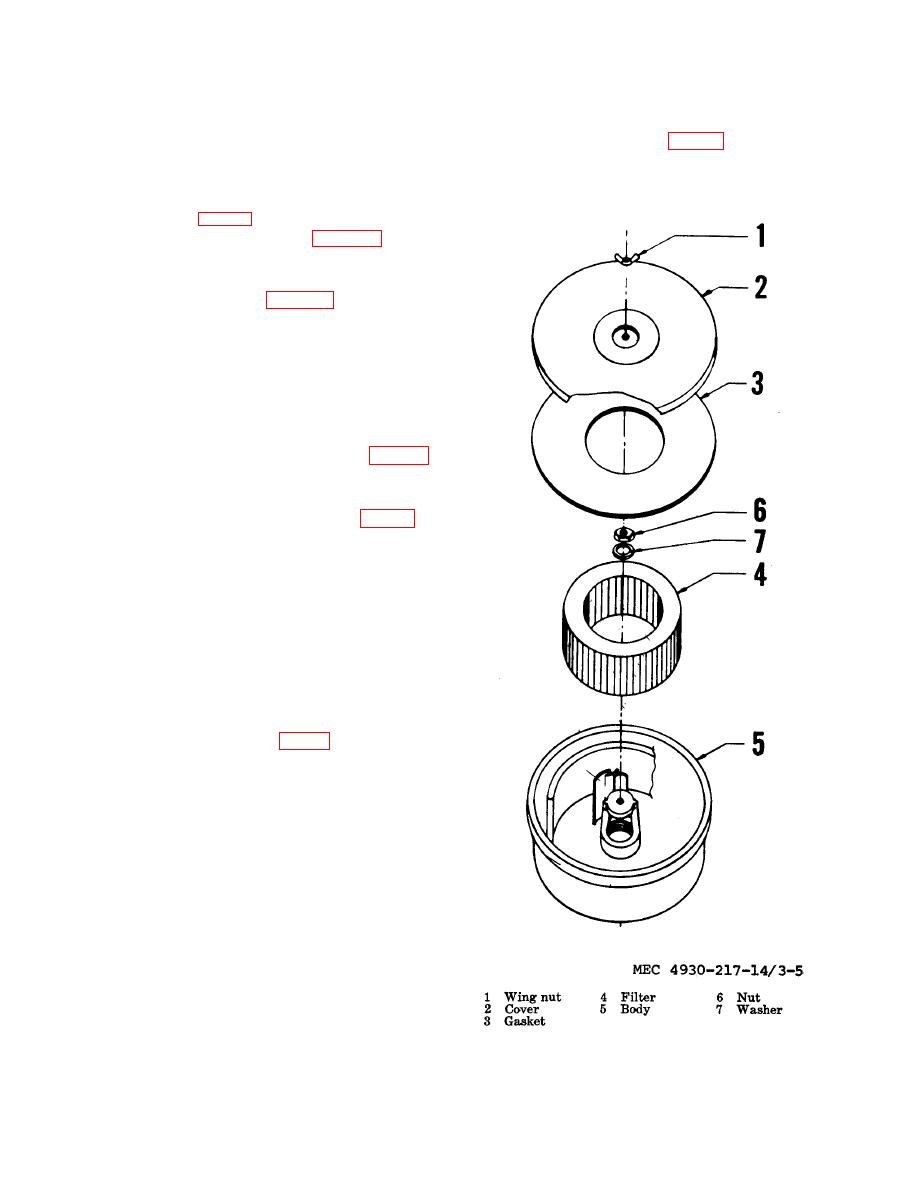

equipped with a filter element (4) to filter

out all dirt. The element must be cleaned or re-

placed to insure clean air and to prevent wear

due to dirt. Remove wing nut (1) and cover

(2) to gain access to the filter element. Re-

placement of the element is preferred.

c. Air Receiver. Clean the air receiver with

an approved solvent. Clean the tank with a

wire brush. Inspect all parts for dents, bends,

and other damage. Report all damage. Drain

the air receiver of moisture by opening the

air tank drain valve (44, fig. 2-3).

d. Compressor Drive Belt Adjustment. Ad-

just as follows:

(1) Loosen the engine attaching hard-

ware.

(2) Move the engine toward or away from

the compressor and check for proper belt

tension at the midway point between the pul-

leys. When belt can be depressed to inch,

tension is proper.

(3) Tighten the engine attaching hard-

ware and replace the belt guard.

3-11. Engine

Refer to TM 5-2805-203-14 for servicing the

engine.