f. Adjustments.

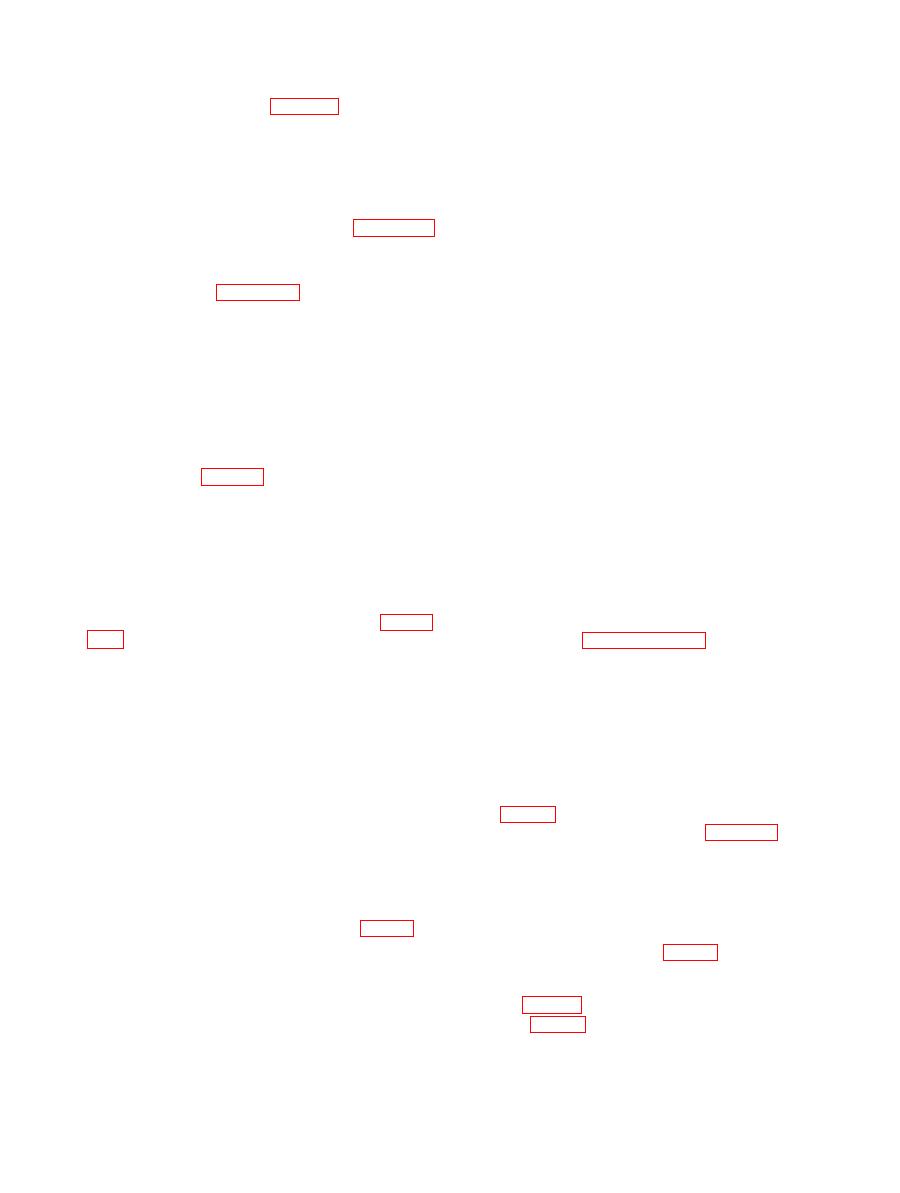

3-107. Control Valve (fig. 3-30)

(1) Single shot delivery.

a. General. The two control valves are of the

(a) Loosen locknut (26).

squeeze lever type and are used to control the

(b) Turn adjusting screw clockwise

amount of grease being dispensed.

until a definite stop is felt, then turn counter-

clockwise approximately one and a quarter

b. Removal. Remove the two grease control

turns.

valves in a similar manner as the two high

pressure control valves described in paragraph

Note. Do not force the adjustment screw.

(c) Tighten locknut (26).

3-102.

(2) Amount of single shot delivery.

c. Disassembly. Disassemble the control

(a) Leave pressure on nose and loosen

valve as shown in figure 3-31.

locknut (26).

(b) Turn adjusting screw clockwise

d. Cleaning, Inspection and Repair.

(tightening) to decrease the amount of lubri-

(1) Clean all parts in an approved clean-

cant delivered; turn counterclockwise (loosen-

ing solvent.

ing), to increase the amount.

(2) Replace all packing in the control

Note Turn the adjustment screw about an

valve.

eighth of a turn at a time.

(c) While adjusting open the control

(3) Inspect parts for damage or defects.

valve several times to determine whether or

Replace parts if necessary.

not the adjustment is satisfactory.

(4) Compress spring plunger and seat

(d) Tighten locknut.

assembly (18, fig. 3-31) to clean and inspect.

(3) Lever adjustment. The lever (3) of

If seat is scored, replace.

the control valve should be adjusted so there

(5) Clean the strainer on the hydraulic

1

is a /8 inch clearance between the bottom of

coupler (1).

the hole in the lever and the extension (2)

without a lubricant delivery. Adjust hex

(6) Replace all worn parts with new

parts.

socket setscrew (4) until the handle has the

1

/8 inch clearance.

e. Reassembly. Reassembly of control valve

is the reverse of disassembly. Refer to figure

g. Installation. Installation is the reverse of

removal. Refer to paragraph 3-102.

Section XIX. LUBRICATING EQUIPMENT

grease gun as it is merely stored in the lower

3-108. General

drawer assembly.

This section contains information on the oil

suction gun, the air operated oil spray gun,

3-111. Portable Lubricator

the grease gun, the pneumatic gun, the port-

a. Removal. Remove the portable lubricator

able lubricator assembly, pumps, regulators,

(61, fig. 3-8) from its storage bracket (62),

and gages.

and the lubricator is ready to use (para 2-27).

3-109. Oil Suction Gun

b. Installation. Return the portable lubri-

No removal or installation is necessary for this

cator to its storage bracket.

piece of equipment as it is a hand operated

oil suction device. Simply lift it from its

storage position in the lower drawer (fig. 2-5).

a. Removal. The oil spray gun is stored in

After completed operation, return to storage

the upper drawer assembly (fig. 2-6) and has

position.

no removal operation. However, during opera-

tion the oil spray gun is threaded to the air

3-110. Grease Gun

No removal or installation is necessary for the

gun (16, fig. 3-8). Remove the oil spray gun