DIRECT AND GENERAL SUPPORT MAINTENANCE

INSTRUCTIONS

Section I. GENERAL

4-1. Scope

For record and report forms applicable to

These instructions are published for the use of

direct and general support and depot main-

direct and general support maintenance per-

tenance, refer to TM 38-750.

sonnel maintaining the lubricating and serv-

icing unit. They provide information on the

Note. Applicable forms, excluding Standard Form

maintenance of the equipment, which is beyond

46. which is carried by the operator, shall be kept in a

the scope of tools, equipment, personnel, or

canvas bag mounted on the equipment.

supplies normally available to using organiza-

tions.

Section Il. DESCRIPTION AND TABULATED DATA

data on the lubricating and servicing unit refer

4-3. Description

For a complete description of the lubricating

and servicing unit, see paragraph 1-3.

c. Engine Data. Refer to TM 5-2805-203

14 for tabulated data related to the engine.

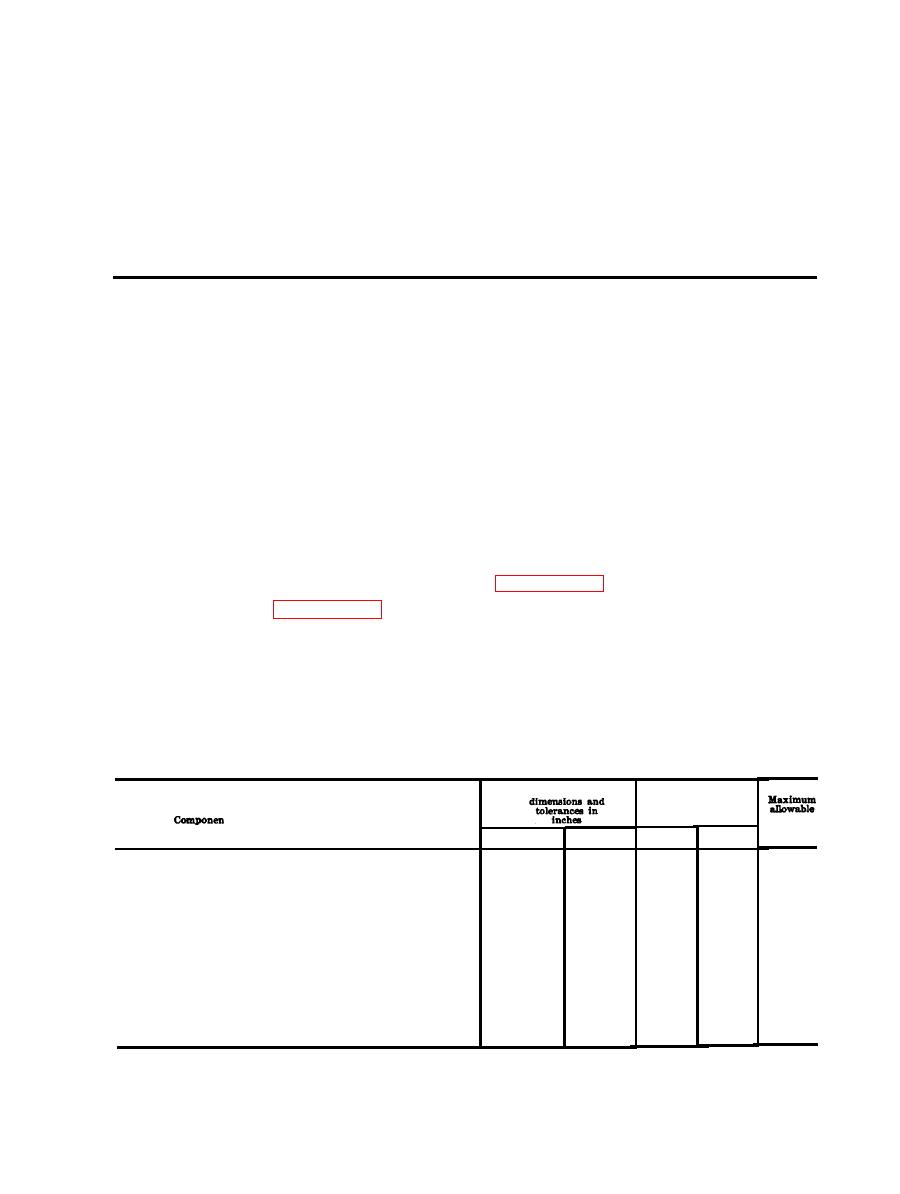

d. Repair and Replacement Standards. Table

a. General. This paragraph contains all the

4-1 lists the manufacturer's sizes, tolerances,

overhaul data pertinent to direct and general

desired clearance and maximum allowable

support maintenance personnel.

wear and clearances for the components of the

b. Lubricator Data. For complete tabulated

REPAIR AND REPLACEMENT STANDARDS

Table 4-1.

Manufacturer's

Desired clearance

wear and

Clearance

Maximum

Minimum

Maximum

Minimum

Crankshaft:

-----

-----

0.0015

End play

0.002

0.0005

Connecting Rods:

0.0004

0.0005

-----

0.0001

-----

Wrist pin

0.0008

0.0016

-----

0.0008

-----

Crank pin

Piston, H.P.

----

-----

-----

-----

Ring gap

0.003

-----

-----

-----

0.0005

Side clearance

0.0005

Piston, L.P.

-----

-----

-----

-----

0.003

Ring gap

-----

-----

___

0.0015

Side clearance

0.0015