LUBRICATING EQUIPMENT REPAIR INSTRUCTIONS

Section I. LUBRICATING UNIT PUMPS

(Used on Serial Numbers 69-29737 through 69-29942)

(c) Unscrew nut (22) and pull primer

8-1. General

piston (21) off.

The air powered pumps are mounted opposite

(d) Unscrew primer rod (20). Remove

the hose reel bank assembly. A high pressure,

piston (11 ) from piston nut (7). Inspect

60 to 1 ratio pump is mounted on the center

packings (8 and 10) and backup washer (9),

lubricant container and one 10 to 1 ratio low

replace if necessary,

pressure pump is mounted on each of the two

(e) Remove piston nut (7) and tap out

outside lubricant containers. The pumps are

ball (6) and spring (5). Clean ball and piston

heavy duty piston type designed for volume

nut thoroughly. Reseat ball using soft metal

operation under extreme conditions.

rod and tapping lightly with small hammer.

(2) Replace packings (6, 7 and 8, fig.

8-1A) as follows:

a. Removal. Remove the high pressure pump

(a) Disassemble tube and rod assembly

as instructed in paragraph 3-1114.

as outlined in step 8-2d ( 1 ).

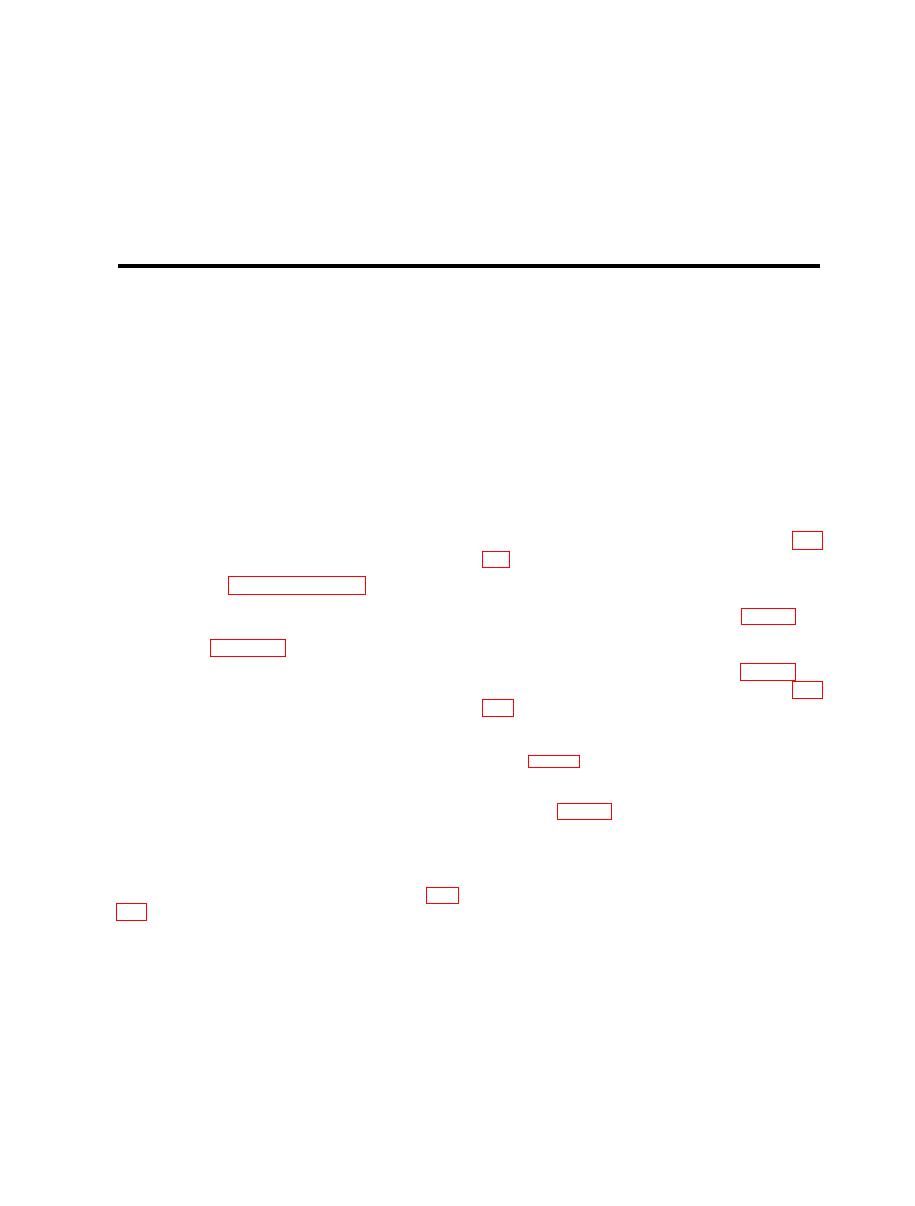

b. Disassembly. Disassemble the high pres-

sure pump in the numerical sequence as

Remove outlet body assembly and drain valve

illustrated in figure 8-1.

assembly.

c. Inspection.

and mounting plate (3). Loosen rod (2, fig.

(1) Clean all parts in an approved clean-

ing solvent.

pressure cylinder support assembly.

(2) Inspect and replace any worn or

Note. It may be necessary to loosen cylinder

damaged parts.

cap (4, fig. 8-1C) and pull out and hold air piston

(3) Inspect threaded surfaces for damage.

assembly.

(4) Replace all parts supplied in parts

(d) Place high pressure cylinder sup-

kit.

port (4, fig. 8-1A) in vise and remove nut

(9). Remove female packing ring (8), six

d. Repair.

V-packings (7) and male packing ring (6).

(1) Clean ball seat and primer valve as

(e) Inspect and replace damaged or

follows:

worn parts.

(a) Remove primer cylinder (17, fig.

Note. Soak V-packings (7) in oil before in-

stalling.

pipe wrench.

Remove O-ring (10), inspect and

(f)

Note. Primer valve assembly will come off

replace if necessary.

when high pressure cylinder is removed.

(3) Remove O-ring or valves in air piston

(b) Remove retaining ring (12),

as follows:

washer (13), packing (14) and backup wash-

(a) Disassemble as outlined in steps

er (15). Replace packing (14) and backup

washer (15) as necessary.

8-2d(1)(2).