TM 5-4930-218-14

bearing cones and rollers in the crankcase.

pits, or burned surfaces. Replace defective bearing

(4) Install the centrifugal unloader (para 7-6). Be

cups.

sure you adjust crankshaft end play when installing

(6) Inspect the crankcase for breaks, cracks,

the unloader.

chips, or other defects. Replace if defective.

(5) Install pistons, piston rings, connecting rods,

c. Reassembly and Installation.

and cylinder block (para 7-8).

(1) Use a suitable bearing cup driver to press the

(6) Install handhole plate and new plate gasket

(7) Install the oil drain plug in the crankcase.

bearing cup in the governor housing (35) in the same

(8) Install flywheel (para 7-2).

manner.

(9) Install compressor (para 4-42).

(2) Press the tapered bearing cones and rollers

(10) Install tube assemblies (para 4-46).

(12, fig. 7-3) on the crankshaft (13), You should make

certain that cones and rollers are seated firmly

against the crankshaft shoulders to insure a correct

reading when determining crankshaft end play.

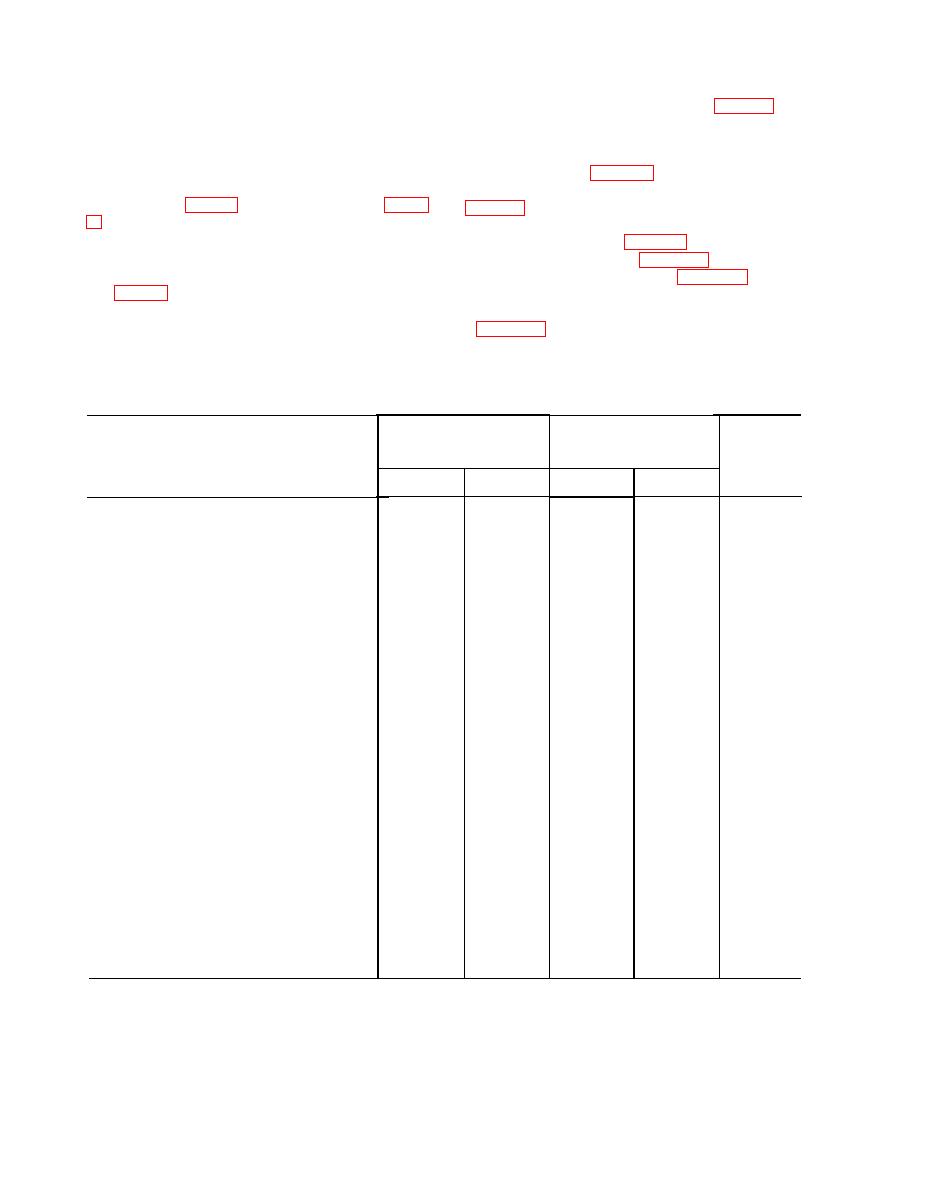

desired clearances, and maximum allowable wear and

clearances.

(3) Install the assembled crankshaft and tapered

Manufacturer's dimensions

Desired

Maximum

and tolerances

clearance

allowable

in inches

Points of measurement

wear and

clearance

Min.

Max

Min.

Max.

Cylinders:

0.0060

Bore, low preasure. . . . . . . . . . . . . . . . . . . . . .

4.6250

4.6250

0.0020

0.0030

0.0060

............ ..........

Bore, high pressure. . . . . . . . . . . . . . . . . . . . . . .

2.5000

2.5005

Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.0010

0.0010

0.0020

............ ...........

Out-of-round ... . . . . . . . . . . . . . . . . . . . .

0.0010

0.0010

Crankshaft:

1.3760

1.3770

Journal size, main bearing. . . . . . . . . . . . . . . . . . .

1.6230

1.6250

Journal size, connecting rod. . . . . . . . . . . . . . . .

0.0005

Journal out-of-round. . . . . . . . . . . . . . . . . . . .

Journal taper. . . . . . . . . . . . . . . . . . . . . .

0.0002

Pistons, piston pins, piston rings:

0.0015

Piston size, low pressure. . . . . . . . . . . . . . . . .

4.6200

............

...........

4.6195

2.4970

2.4975

0.0015

...........

............

Piston size, high pressure . . . . . . . . . . . . . . . .

.......

Piston pin diameter, low pressure. . . . . . . . . .

0.8125

0.0010

0.8122

..........

.....

0.0010

0.8122

............

Piston pin diameter, high pressure. . . . .

0.8125

Piston pin length, low pressure. . . . . . . . . . . . . . .

2.1250

2.1350

0.0002

0.0009

2.1250

2.1350

0.0009

0.0002

Piston pin length, high pressure. . . . . . . . . . . . . .

............

0.0009

. . . . . . ...

0.0002

Piston pin clearance in piston. . . . . . . . . . . . . . . .

Piston-to-cylinder clearance,

0.0055

............ ...........

0.0054

low pressure . . . . . . . . . . . . . . . . . . . .

Piston-to-cylinder clearance,

0.0030

............ . . . . . . . . . .

0.0025

high pressure . . . . . . . . . . . . . . . . . . . . .

Piston ring side clearance,

.........

0.0025

. . . . . . . . . . . . 0.0010

low pressure . . . . . . . . . . . . . . . . . .

Piston ring side clearance,

0.0010

... . . . . . . . . .

high pressure. . . . . . . . . . . . . . . . . . . . . . . . . .

..........

0.6045

Piston ring gap, low pressure. . . . . . . . . . . . . . . . .

0.0130

0.0230

Piston ring gap, high pressure. . . . . . . . . . . . . . . . . .

0.0170

0.0070

Connecting rods and journals

. . . . . . . . . . . 0.0003

Bearing running clearance . . . . . . . . . . . . . . .

............

0.0016

.......

Bearing side clearance. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 0.0040

0.0012

1.3760

1.3770

Bearing internal diameter . . . . . . . . . .

1.6270

1.6283

Rod internal diameter (cold) . . . . . . . . . . . . . . .