underside of the valve body and the mounting surface of the cylinder head. Then tighten the lock nuts

securely.

(3) Install an end washer (8), 14 spring washers (9), a spacer (10), and a special nut (11) on each mounting

stud. Tighten the special nuts evenly all the way around until the distance from the uppermost spring

washer to the top surface of the valve body measures 1/8-inch.

(4) Connect the tees (17, fig. 41), connector (16) and tube assemblies (15) to the valve assembly, or

assemblies as they are installed.

126. Compressor Cylinder Head

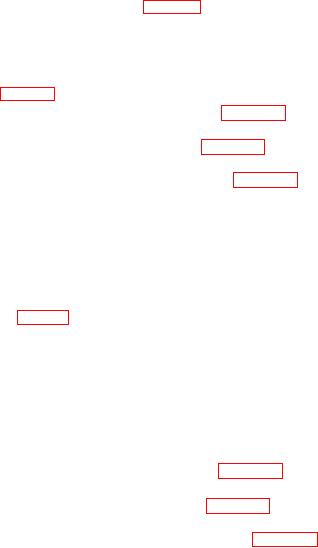

a. Removal (fig. 60).

(1) Remove the air discharge manifold (par. 124a).

(2) Remove the compressor valves (par. 125a).

(3) Remove the compressor air cleaners (par. 123a).

(4) Remove the 17 hex nuts (6) and special washers (5) from the head mounting studs (18), and lift the

compressor cylinder head (13) and gasket (19) straight up from the studs.

b. Cleaning and Inspection. Clean out the inside of the cylinder head with compressed air. Wipe the head casting

with a cloth dampened in cleaning solvent and dry with compressed air. Discard and replace the cylinder head gasket.

c. Installation (fig. 60)

(1) Place the new cylinder head gasket (19) on the mounting studs (18). Lift the cylinder head into position

above the crankcase, and carefully lower it onto the mounting studs.

(2) Install the 17 special washers (5) and hex nuts (6). These nuts must be tightened with a torque wrench to

90 foot-pounds. Tighten the center nut first; then work alternately toward each end of the cylinder head,

using a cross-cross pattern, until all nuts are tightened.

(3) Install the compressor air cleaners (par. 123c).

(4) Install the air discharge manifold (par. 124c).

(5) Install the compressor valve assemblies (par. 125c).

Section XIII. HOUSING

127. Description

The engine-compressor housing protects the equipment from rain, snow, and accidental mechanical damage. Keep

the covers closed except when inspecting or repairing the unit. The housing includes-top, side, rear, and radiator covers

137