holes alined during installation. Install the rocker arm assembly on the four mounting studs, with the valve

contact faces of the rocker arms resting on the ends of the valve stems.

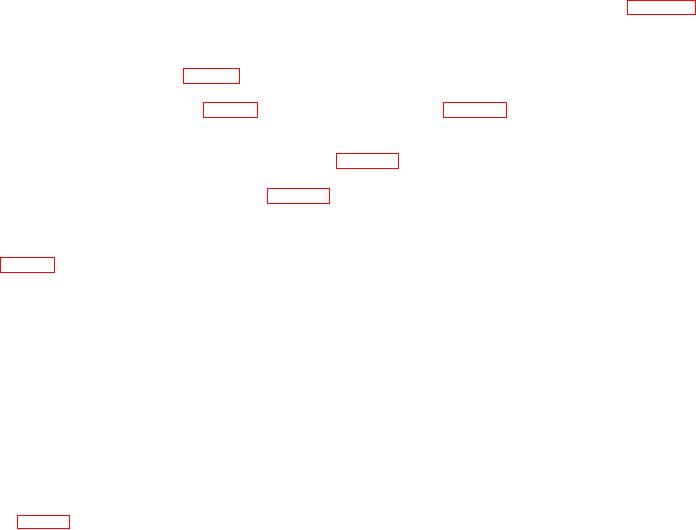

(4) Install and tighten the 17 hex nuts (14) and special washers (13), following the sequence shown in figure 58.

Tighten all cylinder head nuts with a torque wrench to 90 foot-pounds of torque. These nuts must be

retightened after the engine is warm and before adjusting the valve clearance.

(5) Connect the tube assembly (3, fig. 57) to the elbow (4) in the aftercooler end of the cylinder head.

(6) Install all spark plugs and cables (par. 96) and the engine manifolds (par. 120c).

(7) Run the engine at a fast idle for 15 minutes. Then retighten all cylinder head nuts with a torque wrench to

90 foot-pounds and adjust the clearance of all valves (par. 121).

(8) Install the cylinder head cover and gasket (par. 119c).

123. Compressor Air Cleaners

a. Removal (fig. 59).

(1) Two pairs of air cleaners are mounted at the back of the compressor cylinder head. Both pairs are identical

in construction and are mounted in the same fashion.

(2) Reach behind the air filter connection (8) and remove the self-locking nut (11) and copper washer (10) from

the long mounting stud (9).

(3) Lift the assembled air cleaner and its gasket (7) from the cylinder head port. Remove the covers (4) and

filter elements (6) from the air filter connection.

b. Cleaning and Inspection. Blow out the filter elements and the inside of the filter connection with compressed air.

Wipe the exterior of the filter connection and cover with a cloth dampened with cleaning solvent. If the filter element

appears to be clogged or caked with dirt it must be replaced. If, upon inspection, gaskets have loosened from the air

cleaner, remount and adhere with Pliobond or No. EC11 cement.

c. Installation (fig. 59).

(1) Insert the filter elements (6) into the filter connection (8) and install gasket (7) and the cover (4), snapping

the ends of the spring (3) under the cast lugs on the connection.

133