b. Press down the trigger safety locking plunger on the top of the saw handle.

c. Depress the trigger and guide the saw through the work. Do not force the blade into the material.

d. When work has been cut through, release the trigger to stop the saw.

e. Never attempt to loosen the telescopic guard or adjust the foot while the blade is rotating.

160. Servicing

a. Changing Blades. Always make certain that the trigger is locked before changing blades. Use the special wrench

provided and remove the saw stud by turning it clockwise. In replacing blade, the saw teeth must point in the direction of

rotation. After the new saw blade is in place, tighten the saw stud securely but not excessively.

b. Lubrication. There are four points of lubrication on the circular saw. Before lubricating any of these points, be

sure to clean around the fittings or plugs to prevent foreign matter from contaminating the grease or oil. One grease fitting

is located on top at the motor housing near the front handle; the other on the right side of the rear handle. The oil plug is

located on the top of the motor housing near the rear handle. The gear plug is located at the top center of the gear case.

Use the lubricants recommended in table I. Note that the gear reservoir oil level can be checked through the inspection

window on the side of the

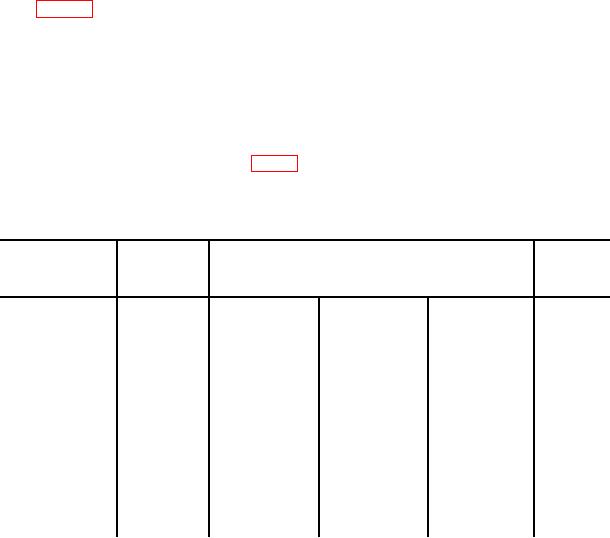

Table I. Lubrication for-Circular Saw.

Temperature

Position

Lubricant

Interval

Below 0F.1

0 to 32 F.1

Above 32F.

Two grease

Grease.

GAA .....

GAA.....

GAA.....

Weekly.

fittings.

automo

tive and

artillery.

Oil reservoir..

Engine

OE-10...

OE-10...

OE-30...

Check

oil...

every 4

hours.

Gear case.....

Gear oil....

GOS .....

GO-75...

GO-90...

Check

every 8

hours.

1 In low temperature. run saw "idle" for few minutes until gear case warms up.

153