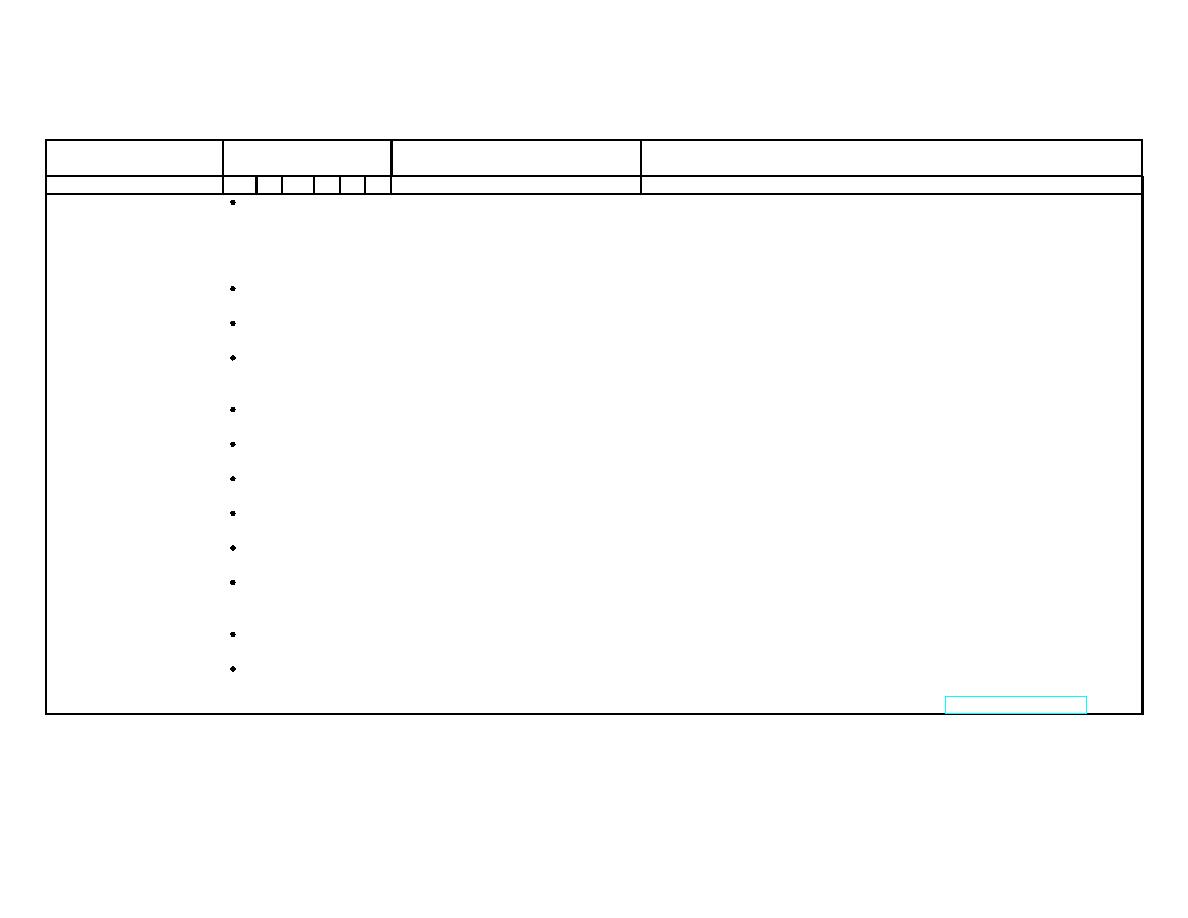

TM 55-1905-223-24-8

Table 2-1. Preventive Maintenance Checks and Services

D - Daily

W - Weekly

M - Monthly

Q - Quarterly

S - Semiannually

A - Annually

Item No.

Interval

Items To Be

Procedures

Checked / Serviced

D

WM

QS

A

1

Oil Tank

Caution

DO NOT OVERFILL!

Maintain between high and low level marks on liquid level red cap

gauge.

2

Air Receiver

Drain moisture accumulation.

3

Air Distribution System

Drain moisture separator and traps.

4

Air Compressor

Give Compressor an overall visual inspection and ensure that safety

guards are in place.

5

Oil Pressure

Check oil pressure when hot. Maintain 18 to 20 psig.

6

Air Compressor / Motor

Check for any unusual noise or vibration.

7

Air Compressor

Check oil for leaks

8

Valves

Operate the safety valves to be certain they are functioning.

9

Coolers

Clean the cooling surfaces of the intercooler and compressor.

10

Filter

Replace or clean air intake filter. Check more often if dirty conditions

exist

11

Air Distribution System

Check the system for leaks.

12

Inspect oil for contamination and change if necessary. Check more

often under dirty conditions. To change, place drain pan under

compressor and remove drain plug (refer to LO 55-1905-223-12.

2-3