TM 9-4310-394-13

Table 4-3. Unit Troubleshooting.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6.

AIR COMPRESSOR AIR VOLUME IS TOO LOW.

Step 1. Check for clogged air compressor filter.

Replace air compressor filter (Refer to paragraph 4-36).

Step 2. Check for loose fittings or cracked tubes on air receiver tank, discharge tube, or intercooler tube.

Tighten all loose fittings and replace any defective tubing.

Step 3. Check for loose V-belt.

Refer to para. 4-7 and adjust V-belt.

If V-belt does not need adjusting, notify direct support maintenance.

7. ENGINE RUNS ROUGHLY.

Check for air in fuel lines.

WARNING

Do not let fuel drip onto any surfaces of the air compressor unit. Fuel can explode and severely injure or kill

operating personnel. Have a container ready to catch any leaking fuel before performing the next procedure.

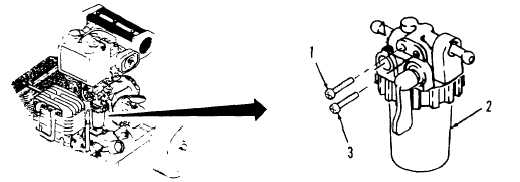

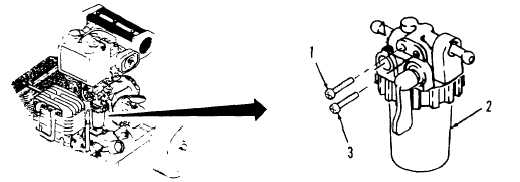

Loosen screw (1) on fuel filter (2) and let fuel leak from loosened screw until no air bubbles appear in

draining fuel. Repeat for screw (3).

Section V. UNIT MAINTENANCE PROCEDURES

4-12. INTRODUCTION. Maintenance procedures at unit level of maintenance include as necessary: removal, cleaning

and inspection, repair or replacement, and installation. Unless the procedure requires special resources or tools, more

than one maintenance person or specific equipment conditions, these are not listed for each maintenance procedure.

They are listed only for those procedures that require them.

4-13