TM 9-4310-397-14

6-4. FUEL INJECTION PUMP REPLACEMENT .

This task covers:

a.

Removal

b.

Installation

INITIAL SETUP

Tools:

Equipment Conditions:

Automotive Maintenance and Repair

Engine removed. (See para 4-72.)

Item 2, Section III, Appendix B

a.

Removal.

CAUTION

Fuel injection pump does get hot and can crack if cold water or steam cleaning is done while

it is running or hot.

(1)

Clean the fuel injection pump, lines, and area around pump with cleaning solvent (item 16, section II,

appendix E) or a steam cleaner.

(2)

Use (75160) JDE-81-1 or (75160) JDE-83 Flywheel Turning Tool (item 15, section III, appendix B) to rotate

crankshaft to position No.1 piston at TDC on compression stroke.

NOTE

If the engine front plate is not to be replaced, proceed to Step 4.

(3)

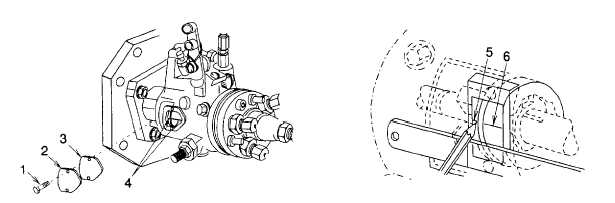

If the engine front plate is to be replaced, remove two timing hole screws (Figure 6-13, 1), cover plate (2),

and gasket (3) from side of pump housing.

(a). Check timing marks (4). If there is a mark on cam ring (rear mark) and governor weight retainer

(front mark) proceed with disassembly.

Figure 6-13. Timing Marks

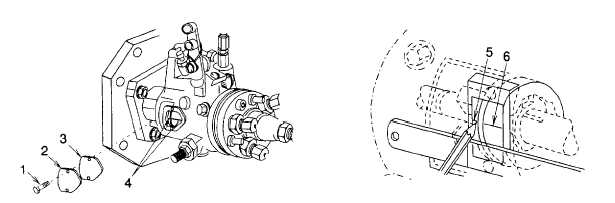

(b). If there is no mark on the weight retainer, scribe a mark on weight retainer (5) directly in line

with mark on cam ring (6).

(4)

Disconnect shut-off wire lead and speed control rod.

6-14