TM 9-4310-397-14

6-4. FUEL INJECTION PUMP TESTING. - Continued

NOTE

If pump shaft cannot be removed from tapered bore of drive gear, strike engine front plate

several blows with a brass drift and hammer.

(12)

Turn cap screw (Figure 6-15, 8) of special tool clockwise until pump shaft is loosened from tapered bore of

drive gear.

(13)

Remove nuts (Figure 6-14, 5) and withdraw pump from the three mounting studs. Be careful not to lose

the Woodruff key in pump shaft.

(14)

Remove special tool. Plug or cap all openings in pump and engine if new pump is not to be installed

immediately.

b.

Installation.

NOTE

If the injection pump drive gear was removed from engine, it must be timed when reinstalled.

Make sure that Woodruff key is in place in pump shaft and aligned with timing gear key way

and that it is tight.

(1)

Using a new gasket (Figure 6-16, 1) (item 49, appendix H) (if installed) and preformed packing (10), slide

pump onto mounting studs.

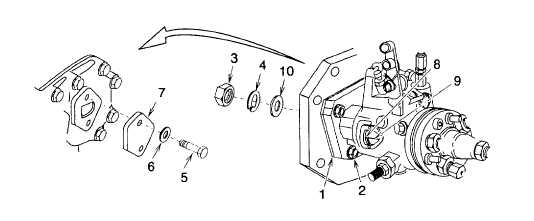

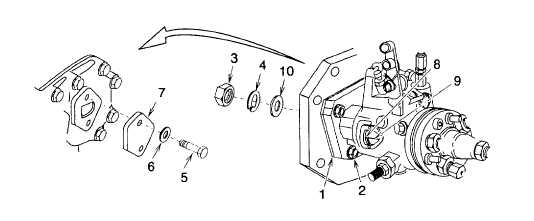

Figure 6-16. Injection Pump Installation

(2)

Screw the three hex nuts (2) onto studs and tighten finger tight only at this stage.

(3)

Install nut (3) and new lock washer (4) (item 50, appendix H), torque drive gear hex nut (3) to 44 ft-lb (60

Nm) torque. Install mounting hole cover (7) with two cap screws (5) and washers (6).

(4)

Check that the three pump mounting nuts (2) are in place but loose. Pivot pump housing away from

cylinder block as far as slots will allow. Then pivot it back far enough to align timing mark on weight

retainer (8) with mark on cam ring (9).

6-16