TM 9-4310-397-14

6-10. CONNECTING ROD, PISTONS, RINGS, AND LINERS AND CYLINDER BLOCK INSPECTION AND

REPAIR. - Continued

NOTE

Liners are reusable if the depth of pits or erosion is less than the amount

specified. When installing these liners, rotate 90° from original position.

The liners should be deglazed and ring sets installed on pistons. If NO

defects are found, proceed to next step.

(c)

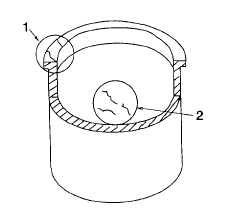

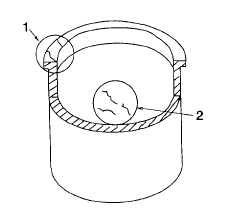

Carefully examine the cylinder liner for signs of fatigue, such as fine cracks in the flange area (Figure

6-81, 1) and cracks in the ring travel area (2).

(d)

Inspect block for cracks or erosion in the preformed packing area. Replace block if any of these defects

are found.

Figure 6-81. Inspect Liner for Cracks

(e)

If any defects are found, replace the liner. If no defects are found, and pistons and liners have passed

all previous checks, proceed to check both for proper specifications.

(f)

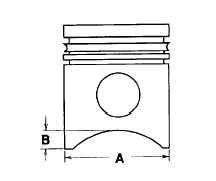

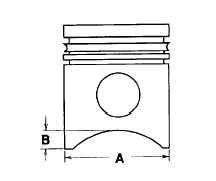

Measure piston skirt (A, Figure 6-82) at right angles to piston pin bore at 0.74 in. (19 mm) from bottom

of piston (B). Record measurement.

Figure 6-82. Measure Piston

6-66