TM 9-4310-397-14

6-10. CONNECTING ROD, PISTONS, RINGS, AND LINERS AND CYLINDER BLOCK INSPECTION AND

REPAIR. - Continued

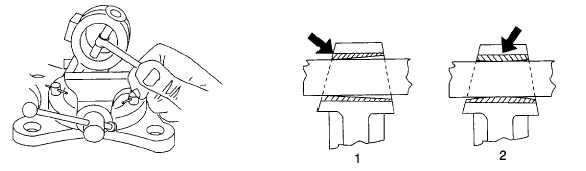

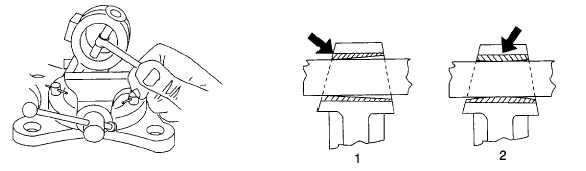

(e)

Insert pin from either side of rod bushing. If pin is free on one end, but tight on the other, the bore could

be tapered (Figure 6-85, 1). If pin enters freely from both sides, but is tight in the center, bore is bell

mouthed (2).

Piston Pin Bushing Specifications

ID of New Piston Pin Bushing (installed)

Small pin .........................................1.376 - 1.377 in.(34.95 - 34.97 mm)

Large pin .........................................1.626 - 1.627 in.(41.30 - 41.33 mm)

Wear Tolerance ............................................................... 0.002 in.(0.05 mm)

Pin-to-Bushing Clearance ...........................0.008 - 0.002 in.(0.02 - 0.06 mm)

Maximum .................................................................. 0.004 in.(0.10 mm)

Figure 6-85. Piston Pin Bushing

(f)

If piston pin bushing replacement is necessary:

1

Push bushing out of connecting rod using driver (item 27, section III, appendix B) for large pin or

(item 26, section III, appendix B) for small pin.

2

Clean bore of rod with medium grit emery cloth.

3

Inspect for cracks or other defects. Make sure that lube oil hole in top of rod is open.

4

Measure bore diameter in two places, 90° apart. If bushing has spun in rod or if measured diameter

is not within specification, replace rod.

Rod piston Pin Bushing Bore

Small pin ........................................... 1.4995 - 1.5005 in.(38.09 - 38.11 mm)

Large pin ........................................ 1.8120 - 1.8130 in.(46.025 - 46.051 mm)

6-70