TM 9-4310-397-14

5

Align lubrication oil hole in bushing with bore in connecting rod.

6

Press a new bushing into rod using (item 27, section III, appendix B) Driver (large pin) or (item 26,

section III, appendix B) small pin.

7

If necessary, hone bushing to obtain a clearance with piton pin of 0.0008 - 0.002 in.(0.02 - 0.06 mm).

(6)

Inspect and clean cylinder block.

CAUTION

All components (including piston cooling orifices), soft plugs and oil gallery

plugs must be removed from the cylinder block for inspection and cleaning.

(a)

Clean block thoroughly using cleaning solvent, pressure steam, or a hot tank.

CAUTION

If cylinder block is cleaned in a hot tank, be sure to remove any aluminum parts

(remove all nameplates). Aluminum parts can be damaged or destroyed by hot

tank solutions.

(b)

Make sure all passages and crevices are cleared of sludge, and grease.

(c)

All coolant passages must be cleared of any lime deposits and scale.

(d)

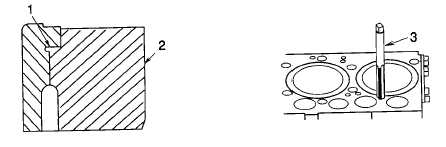

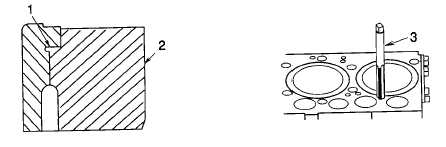

Be sure liner support flange (Figure 6-86, 1) is free of any burrs. If burrs are present, use a small

halfmoon file and lightly file (in a circular motion) burr off at approximately a 60° angle. Do not let file hit

top of cylinder block while filing.

CAUTION

Do not file liner support flange excessively. Excess filing can damage liner

support flange and allow an improper liner fitting. Thoroughly clean all filings

from cylinder block (2).

Figure 6-86. Liner Support Flange

6-71