TM 9-4310-397-14

6-10. CONNECTING ROD, PISTONS, RINGS, AND LINERS AND CYLINDER BLOCK INSPECTION AND

REPAIR. - Continued

(e)

Carefully inspect block for cracks or damage. Replace block if there is evidence of physical damage.

Cylinder block liner counterbore depth is 0.2343 - 0.2357 in. (5.95 - 5.99 mm).

(f)

When determined that the cylinder block is serviceable, clean out threads for cylinder head capscrews in

top deck of cylinder block. Use a 1/2-13 UNC-2A tap (3) approximately 5.0 in. (127 mm) long. Use

compressed air to remove any debris or fluid which may be present in the cap screw hole.

(g)

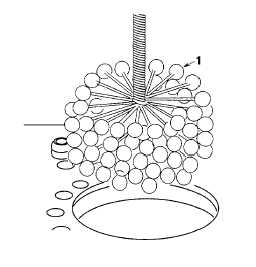

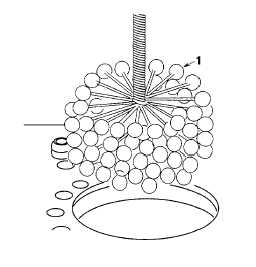

Use Bore Cleaning Brush (Figure 6-87, 1) (item 28, section III, appendix B) to clean bore.

Figure 6-87. Clean Bore

(h)

Thoroughly clean all debris from bore.

(7)

Measure cylinder block.

(a)

Measure main bearing bore diameter. Main bearing bore diameter must be 3.325 - 3.326 in. (84.46 -

84.48 mm). Also measure cylinder block main thrust bearing width. Width must be 1.3235 - 1.3275 in.

(33.62 - 33.72 mm). If bearing caps are damaged, or bore is not within specification, replace cap and line

bore to specifications.

NOTE

Replacement bearing caps are supplied with bearing bore unfinished.

(b)

Measure cam follower bore diameter. New diameter is 1.248 - 1.250 in. (31.70 - 31.75 mm).

(c)

If diameter is more than specified, install a new cylinder block. Service bushings are not available

through service parts.

(d)

New cam follower diameter is 1.245 - 1.246 in. (31.61 - 31.64 mm). Maximum cam follower clearance is

0.005 in. (0.13 mm).

6-72