TM 9-4310-397-14

6-10. CONNECTING ROD, PISTONS, RINGS, AND LINERS AND CYLINDER BLOCK INSPECTION AND

REPAIR. - Continued

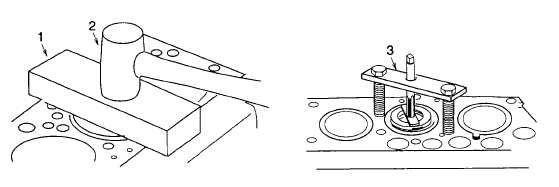

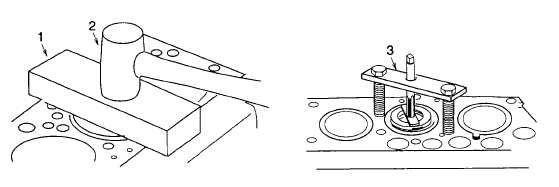

Figure 6-90. Seat Cylinder Liners

NOTE

If you suspect that a packing may have sheared or displaced during lowering into

position, remove and examine the liner and packing assembly. If no damage is

found, check the packings for proper position, resoap the packings and reinstall

liner assembly.

(9) With liners installed, hold in place with large flat washers and cap screws. Turn cap screws snug but do not

tighten.

(10) Clean cylinder liner bores with waterless hand cleaner after installation.

(11) Wipe dry with clean rag.

(12) Install pistons and connecting rods.

(a)

If a new piston and liner assembly is to be installed. Do not remove piston from liner. Push piston out of

liner bottom only far enough to install piston pin.

(b)

New fitted rings are furnished with the correct end gap; therefore, fitting to the liner is not necessary.

(c)

Lubricate piston pin and bushing with oil (item 10, section II, appendix E).

NOTE

Pistons must be installed on connecting rods from which they were removed.

(d)

Assemble pistons and connecting rods, making sure the word "Front" or arrow on top of the piston and

side of connecting rod are on same side. If "Front" or arrow is not visible, install piston on rod so that

offset in combustion bowl of piston is opposite camshaft side of engine.

(e)

Insert piston pin into piston pin bore. Install new piston pin retaining rings. Check to be sure retaining

rings are seated in grooves of piston pin bore.

6-76